When it comes to finding industrial control panel solutions, the world of standards, requirements and desires is often a murky one – many options exist, and it’s important to be clear on exactly what will work best for you.

One of the key differentiators is standard vs. UL508a listed panels, particularly when it comes to having a panel built to a UL508a standard. While not required by law, taking the extra time to ensure you get a UL508a panel enclosure can save you money over the lifespan of the panel.

How? Let’s dig in.

Defining UL508a

Essentially, when a panel is created to meet UL508a, it means the designing engineer has thoroughly researched and vetted each part of the panel to make sure it’s been appropriately tested by Underwriter’s Laboratory (UL) and that it meets UL’s safety standards.

With a UL508a panel, that extra due diligence should result in an end product that ensures the panel will be safe for those around it under a fault condition.

Saving You Money

Though UL508a is often associated with its higher up-front cost, the extra step of ensuring your panel meets the standard can save you money down the line, particularly in insurance costs.

If your insurance company knows your panel is UL508a listed, it can be sure that the panel meets safety requirements and is far less likely to result in an accident, resulting in lower premiums for you.

You’ll also trim costs surrounding part replacement and failure – that extra attention to detail at the front end of the process results in reliable, easy-to-find parts that can save you a headache later.

What Other Standards Exist?

UL508a is far from the only standard to be considered when building an industrial control panel – in particular, NFPA 70 (National Electric Code) and NFPA 79 (the national specification for industrial machinery) are also critical considerations.

Basically, the NFPA 70 standard deals with the installation of electrical equipment, not the design. Its purpose is to ensure that the electrical contractor installing your panel remains safe.

The NFPA 79, on the other hand, outlines specifications for industrial machinery like color codes, labeling requirements, proper mounting and more.

These standards are important to understand when it’s time for a new industrial panel, as NFPA 70 has been adopted in all 50 states, and NFPA 79 is the national standard for industrial machinery and provides valuable authentication of safety.

Let Kasa’s Expertise Guide Your Panel Creation Process

As Kasa, we can leverage our industry-leading expertise to provide you with a safe, quality panel that meets all your requirements and desired standards, from NFPA 70 and 79 to UL508a and UL698a.

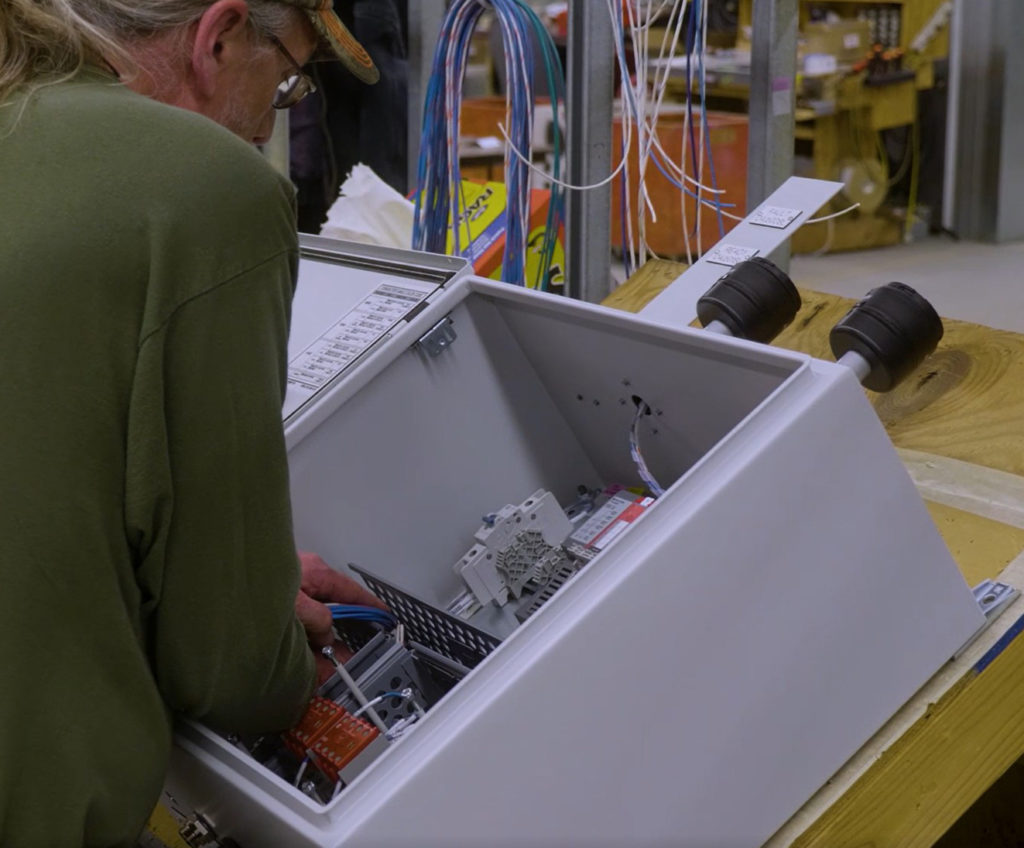

We understand how critical attention to detail is, which is why we take the time to ensure every panel we make is meticulously organized and labeled.

We select components from a wide variety of quality vendors, offering you the best experience and end product possible, and can ship your panel anywhere in the world safely and efficiently. If you’re ready to put your panel build in the hands of the experts, save money and find peace of mind, contact us today at kasacontrols.com/contact/.