Slip Robotics – Automated Trailer Unloading

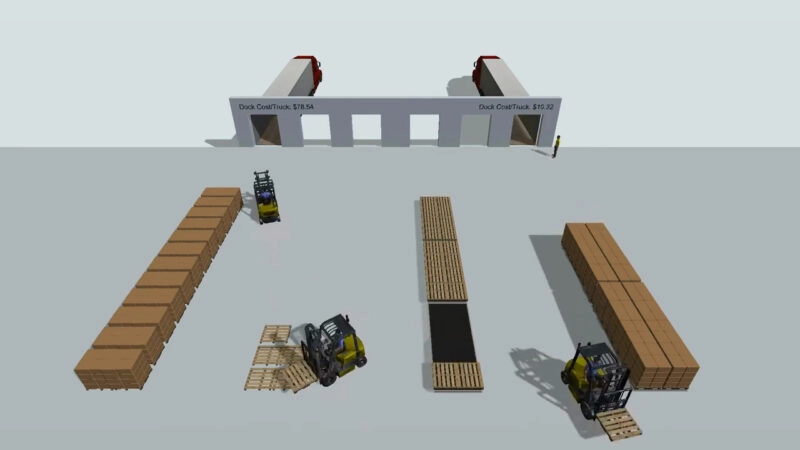

Slip Robotics truck loading and unloading solution loads and unloads trailers in <5 minutes. The solution reduces driver waiting time at the dock, which means that less drivers can move more freight. Slip Robots are a low-cost and reliable solution that require no modifications to trailers or docks to operate.

They reduce costs for shippers, carriers, and customers by improving the operation itself. Slip robots do not require any modifications to docks, trailers, or trucks. They are designed to operate within the current infrastructure that is widely available. Slip robots are operational immediately upon arrival. They don’t require integrations with TMS, WMS, ERP, MES, or any other systems.