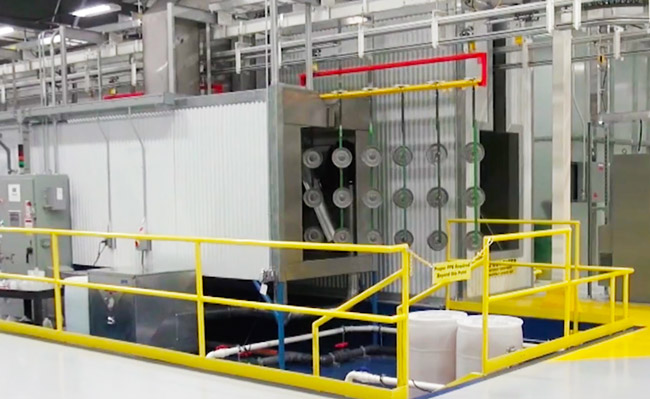

Old vs. New Automated Finishing System Paradigms

Are you still operating under the old automated finishing system paradigm?

Ever since Henry Ford developed the assembly line and its paradigm was applied to automatically finishing parts, the basic thought process has been the same…

Segment all parts that need the exact same finish recipe and create an automatic finishing system to do that single recipe.

For this type of automated finishing system, a monorail continuous chain system or equivalent is great!

But many manufacturers and custom coaters need to paint many different type parts that all require different part recipes. This is easy to do with any manual or batch system, but volume per day is limited, and it has been difficult with automated, chain-based systems.

With the advent of power and free (P&F) chain-based systems, recipe flexibility was enhanced, and parts could be routed to different processes, stopped, sped up or slowed down per drive and chain.

Still, these systems lacked some level of needed flexibility. For example, let’s suppose you have a power and free system that routes some parts through an inline shot blast. In general, that part of the chain will be configured to run at a certain feet per minute. It should be possible to speed up or slow down that loop of chain, but it would not be likely that a company would load something that requires 5 fpm in the blast right after another item that can speed through at 20 fpm – the manufacturer would still need to segment the parts that require more time in the blast from those that require less time. Similar examples could be made for other pretreatment processes when parts are in the wash, in the booth, and in dry or cure ovens, etc.

But what if you had a Recipe Based Finishing System?

With a recipe-based system, carriers of parts moving through a system loaded with dissimilar parts per carrier can run back-to-back. Each carrier can be treated differently based on the process data entered into the system as its “recipe.”

There would no longer be a need for batching your whole line or long segments of your line with like parts to get quality. Work in progress would be reduced, and scheduling of work on the finishing system would be greatly simplified.

With an IntelliFinishing system, users enter commands or process instructions for each part family or group of similar parts, creating a “recipe.” The recipe is selected manually or automatically using scanners or other technology at the loading point for that carrier. All of those like parts on that carrier will then receive the same process. If you next have a different carrier of parts requiring a different recipe, all the operator needs to do is select that recipe at the load-area HMI screen or use their integrated scanner. When that carrier gets to a process area, the system will automatically run the selected process for that part family.

So, what does this mean per typical finishing process?

In a shot blast:

Shot blast recipes typically vary by the speed of the product though the blast and/or the intensity of the shot blast system itself. Either or both can be integrated into a recipe set of options. For example, one customer of IntelliFinishing typically runs his blast at 5 fpm. A 10 ft carrier full of parts or loaded with a single large part can then be shot blasted in about two minutes, plus travel time to the shot blast and travel time out of the shot blast area. But, with his IntelliFinishing system, he can change the speed of the carrier through his blast as needed, and he has recipes that include 8fpm, 10fpm, 15fpm and even 20fpm, etc. Even relatively lightweight gauge items can now be run through his blast at the 20fpm speed without damaging the metal. This customer even includes a recipe for some extremely dirty/rusty parts that routes the carrier to back up after the first pass in the blast and re-blast a second time.

In the wash:

Wash recipes allow for different types of metals or parts with different pretreatment requirements to each have their own unique wash process. For example, it is possible to remain longer in a section, skip a section, increase or decrease the wash spray pressure, or even bypass the whole wash based on the recipe. If you have changes in your wash process due to extra-dirty parts or changes in chemicals requiring your system timing to be different, all you need to do is update your recipe. Since chemical companies are constantly improving their products, the ability to use a recipe means you can take advantage of these new products and no longer be locked into the chemical recipe of the day when the system was created.

Wash recipes allow for different types of metals or parts with different pretreatment requirements to each have their own unique wash process. For example, it is possible to remain longer in a section, skip a section, increase or decrease the wash spray pressure, or even bypass the whole wash based on the recipe. If you have changes in your wash process due to extra-dirty parts or changes in chemicals requiring your system timing to be different, all you need to do is update your recipe. Since chemical companies are constantly improving their products, the ability to use a recipe means you can take advantage of these new products and no longer be locked into the chemical recipe of the day when the system was created.

In the coating application:

In the coating application area, displays show the process for each part coming through, where to apply the coating, which color, and any special instructions unique to those parts. For applications with masking options, the work instructions show pictures of where to apply masking, caulking, or any other special procedures. And, of course, part of the recipe is simply which booth or set of booths the parts should flow to so that efficiencies are maintained. For example, on IntelliFinishing Systems, it’s common to have dedicated booths for the most common colors that rarely get changed, but other booths with quick-change capabilities. Items are thereby always routed to the most appropriate booth and the need to segment and schedule parts by color is eliminated.

In the coating application area, displays show the process for each part coming through, where to apply the coating, which color, and any special instructions unique to those parts. For applications with masking options, the work instructions show pictures of where to apply masking, caulking, or any other special procedures. And, of course, part of the recipe is simply which booth or set of booths the parts should flow to so that efficiencies are maintained. For example, on IntelliFinishing Systems, it’s common to have dedicated booths for the most common colors that rarely get changed, but other booths with quick-change capabilities. Items are thereby always routed to the most appropriate booth and the need to segment and schedule parts by color is eliminated.

In the dry off and cure ovens:

Thick parts and thin parts do not typically require the same amount of time for drying off or curing. Even color variation or different paints and powders may create the need to vary gel and final cure timing and/or temperature. With a recipe-based system, parts that have 20-minute cure time and parts that have a 40-minute cure time can be run on the same system at the same time without affecting any other upstream or downstream process. In fact, it’s common with an IntelliFinishing system to run multiple lane ovens, so flexibility and throughput are each enhanced. Faster curing items can pass the slower curing items in the cure process, just like having a multiple-lane highway increases the speed of traffic through a city compared to single-lane options. And, you will no longer over-bake your thin parts just to make sure that your thicker, longer curing parts get cured as desired. Ovens can adjust temperature, air turns and cure time depending on the parts loaded per carrier and system design options.

So, is it time for you to consider a different automated finishing paradigm?

Maybe something leaner, with less transportation, system, and manpower waste?

Something that can operate with just-in-time efficiency?

Give IntelliFinishing a call and discuss your finishing needs with our representatives. We’ll honestly let you know if what you need requires our type of system flexibility or if a more traditional approach would be adequate.

By the way, if you found this article intriguing, watch this video of one of our customers explaining why they like their recipe-driven IntelliFinishing system.

There’s no better way to investigate this proven technology than by visiting one of our many systems. Make arrangements for a system tour by calling us at 785-309-0356 or emailing info@intellifinishing.com to learn more.