TMC Pioneers Precision Vibration Control Equipment to Safeguard Nanoscale Technologies

As technology has become increasingly precise and powerful, yet smaller in size, the need to ensure nanometers of precision in design and operation has risen dramatically. Any minuscule vibration or shift can potentially be catastrophic to such delicate machinery, highlighting the importance of reliable vibration control equipment.

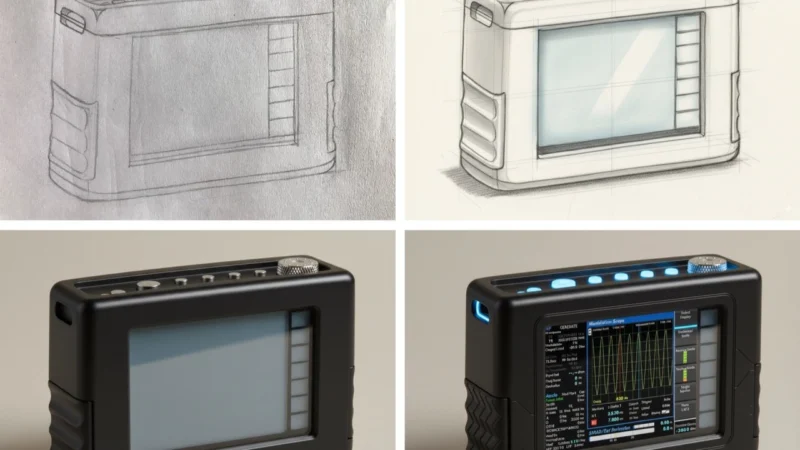

In a recent episode of “Made in America,” the show features TMC, a leading manufacturer of vibration and isolation control tables, based in Peabody, Massachusetts. The episode provides an inside look into TMC’s vertically integrated manufacturing process, demonstrating how their state-of-the-art technology helps to ensure the production, quality control, and use of these tools is as robust and precise as the measurements and functions they perform.

TMC’s vibration isolation tables, for instance, use a mass on a damp spring concept to prevent floor vibration from affecting precision devices, such as electron microscopes or microchips. Using this technology, clients can avoid using makeshift solutions and focus on their core work, knowing their equipment is operating under optimal conditions.

One of TMC’s unique strengths is its dual competencies: expertise in low amplitude, low frequency building floor vibration operation and dedication to vertical integration. This allows the company to design and manufacture solutions with unparalleled precision, responding directly to the needs of various industries from semiconductor manufacturing to materials research.

In conclusion, companies like TMC play a critical role in maintaining the quality and precision of modern technologies, from consumer electronics to advanced scientific equipment. With their focus on innovation and quality control, they provide solutions like their vibration control equipment that help navigate the complexities of manufacturing at the nanoscale level.