Raising the Bar in Concrete Forming: Gates’s Innovative Cam Lock Wall Ties

In the world of concrete forming, challenges are as solid as the structures they aim to build. Traditional methods have often proven time-consuming, labor-intensive, and with outcomes less precise than desired. Recognizing these hurdles, Gates, a vanguard in the construction industry, has developed an ingenious solution that not only addresses these problems but also redefines the standards of concrete forming: the Cam Lock Wall Ties.

From their state-of-the-art Colorado manufacturing facility, Gates produces wall ties in various configurations and cone applications, creating an innovation that is revolutionizing the sector. As articulated by a company representative during their recent presentation, the standout features of Cam Lock Wall Ties reveal Gates’s commitment to efficiency, flexibility, and safety.

Cam Lock Ties are embedded with self-spreading metal washers in each cone, preventing the forms from moving inward. The cones self-center into a thirteen-sixteenth-inch hole, enabling easy, accurate installation. A distinctive feature is the addition of anchor bends that stop the ties from rotating during breakback, ensuring stability throughout the process.

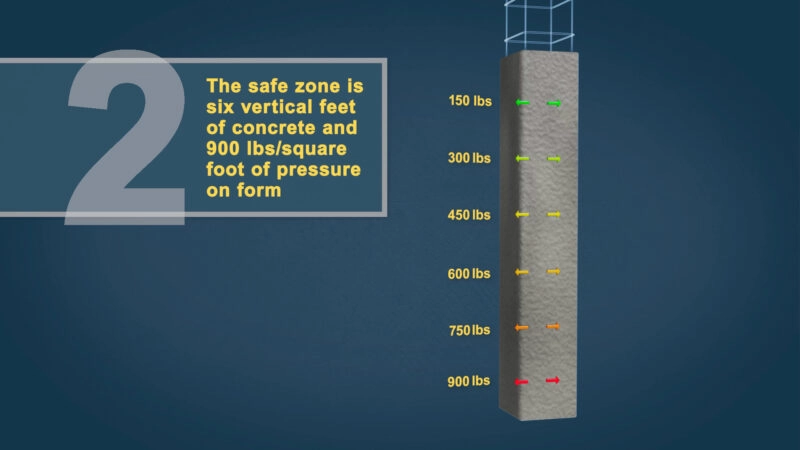

One of the key aspects of Gates’s Cam Lock ties is their uniform end length. By eliminating the need for long short end ties, Gates simplifies the installation process, reducing time and labor costs. Made from four-gauge high carbon wire, these ties boast a safe working load of 2300 pounds with a 2:1 safety factor, demonstrating a commitment to robustness and safety.

An impressive feature is the ability to accomplish different breakback depths by merely changing the cone style. Decones leave a one-inch diameter by a one-inch deep hole, while Encones leave a one and one-sixteenth inch diameter by a one and a half inch deep hole at the concrete surface. Arcones offer a two-inch wire breakback, leaving a one and one-sixteenth inch diameter by a two-inch deep hole.

Cam Lock Wall Ties are highly adaptable, catering to unique forming demands such as one-sided or blind-sided forming. Their ends can be threaded for coupler insertion and they can be fabricated to work seamlessly with stay form, corrugated steel, or plywood.

Further, Gates provides the option of adding a neoprene water stop to the wire tie, effectively preventing moisture from traveling down the tie. Unaffected by commonly used form oils, these water stops are one-inch diameter by three sixteenths thick.

Cam Lock ties can also be manufactured with a G washer, with a one-eighth inch wire breakback, leaving an inch and one-eighth diameter by one-eighth inch deep hole at the concrete surface.

The introduction of Gates’s Cam Lock Wall Ties marks a significant step forward in the construction industry, promising improved efficiency, precision, and safety. It’s more than just a product; it’s a comprehensive solution that addresses long-standing challenges in concrete forming. As the industry moves towards smarter, more innovative solutions, Gates leads the way, showing once again that when it comes to revolutionizing the construction sector, they have the right ties that bind.