Do Tesla’s Outages Reflect a Software Challenge for OEMs?

Earlier this year, Tesla users found themselves in a bit of a digital pickle when the car company’s mobile app experienced a worldwide outage, which users need to lock, unlock and start their vehicles. Though the app-based access point is meant to create ease of use and an elevated tech-focused experience, it acted as a reminder to the consumer, and the OEMs, how vulnerable software- and network-based services are for cars, especially when they’re essential for accessing your car.

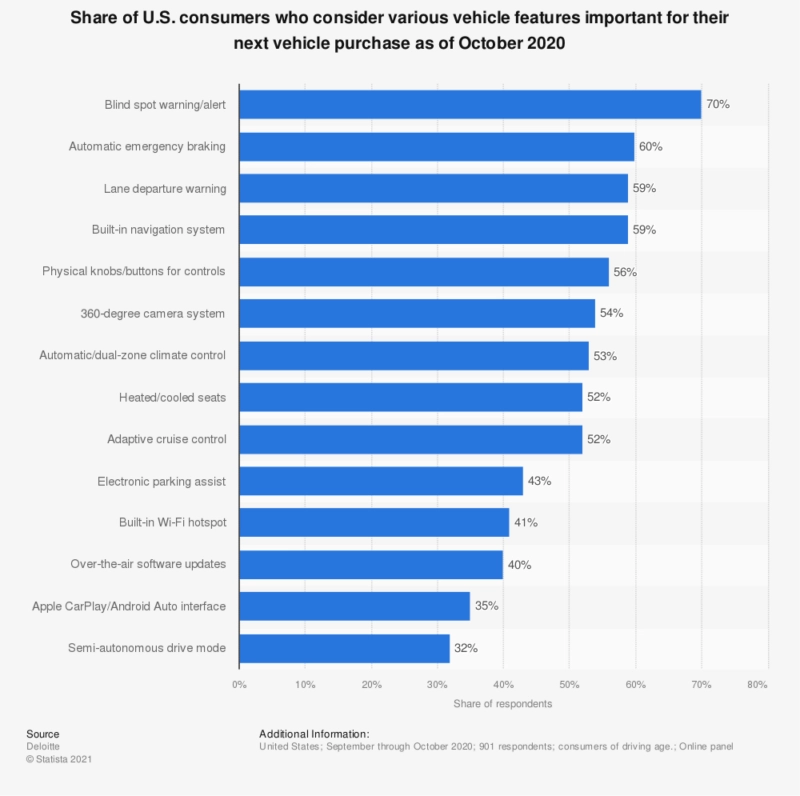

This example only scratches the surface of a larger trend of smarter car features, meaning more software code and more software-related bugs and defects. Smart features are becoming a consumer expectation & baseline.

A Global Automotive Consumer Study by Deloitte found the majority of consumers overwhelmingly prioritize smart features from blind spot warning to automatic emergency brakes to adaptive cruise control, all of which need software code.

Research by Sibros in early 2020 pulled from the National Highway Traffic Safety Administration data, found 2019 reached an all-time-high in software recalls, a threefold spike from 2009, which affected more than 15 million cars in the U.S.

Other recent examples include Tesla’s November recall of almost 12,000 cars due to a glitch in its full self-driving software. Jeep also recalled around 100,000 new Grand Cherokees and Wagoneers due to a software glitch that turns off the car’s airbags.

For perspective on this story, we sourced two experts from Canada’s University of Windsor: Professor of Mechanical & Automotive Engineering Dr. Peter Frise, and Associate Professor Electrical and Computer Engineering, and Co-Director of the SHIELD Automotive Cybersecurity Centre of Excellence, Mitra Mirhassani. Scroll down to the rest of the article for their breakdown tracking trends in software defects and advice for how OEMs need to rethink their production, testing, and network development processes to stay ahead of the smart car software defect curve.

Outages such as Tesla’s are very common, but that is partially due to the lack of connected cars on the road yet, according to Dr. Frise.

“Their systems seem to work okay when they work, but when they don’t work, it creates a lot of havoc. As these kinds of systems become more common, we may start to see this more often, and it can certainly create a lot of heartburn for people,” said Dr. Frise.

Dr. Peter Frise

Mirhassani agreed with Dr.Frise. Mirhassani says the high defect rate is partially because OEMs often outsource codes.

“For the OEM to deal with all these softwares that are coming from all the different sources, to test them to check them, to make sure that they work all of them perfectly, nicely, securely, and guarantee safety is a near impossible task,” said Mirhassani.

Mirhassani projects more defects in the coming years. She believes the reason will be because of constant and new developments in the field.

“It is additional EV and additional AI that is going to cause more chaos. So the expectation is that there will be more failures unfortunately related to the software and the integrations of them,” said Mirhassani.

Mitra Mirhassani

Constant outages and defects don’t come with zero consequences. According to Dr. Frise, OEMs will take a hard reputational hit from these issues.

“The last thing that any manufacturer, or any business wants to do is inconvenience and annoy its own customers,” said Dr. Frise. “You can imagine lots of scenarios when somebody urgently needs access to their car. They have a hospital trip that they’re in the process of making, or an important appointment or a meeting or something.”

As for mission critical jobs such as freight transportation and public transit, OEMs will need to adjust approaches to software development and network management. Dr. Frise suggests that OEMs should look towards the aeropspace industry. He says the aerospace industry is reliable because of their redundancy.

“A modern airplane will have three or possibly even four separate control systems,” said Dr. Frise. “That input goes into a computer and four different systems have to figure out what the correct response is for the airplane, what should the control surface do on the wing, and then they have to vote on it.”

Unfortunately, Mirhassani thinks there is no simple solution for OEMs to solve the glitch and defect issues.

“The problem is going to be larger than what an OEM can afford. And on top of everything else, most of the things we see these days are defects related to safety. Security is an afterthought,” said Mirhassani.

While there is no easy fix, Mirhassani believes a good start would be investing in smarter software testing. Mirhassani also believes there are a few steps OEMs could take to keep the defects at somewhat of a bay.

“We have to start thinking about how we can create a universal framework around the safety and security of the cars,” said Mirhassani. Enabling this “requires a coalition of sharing information and data between the OEMs. If they can integrate or develop more of the codes in house, then there is a little bit more possibilities.”