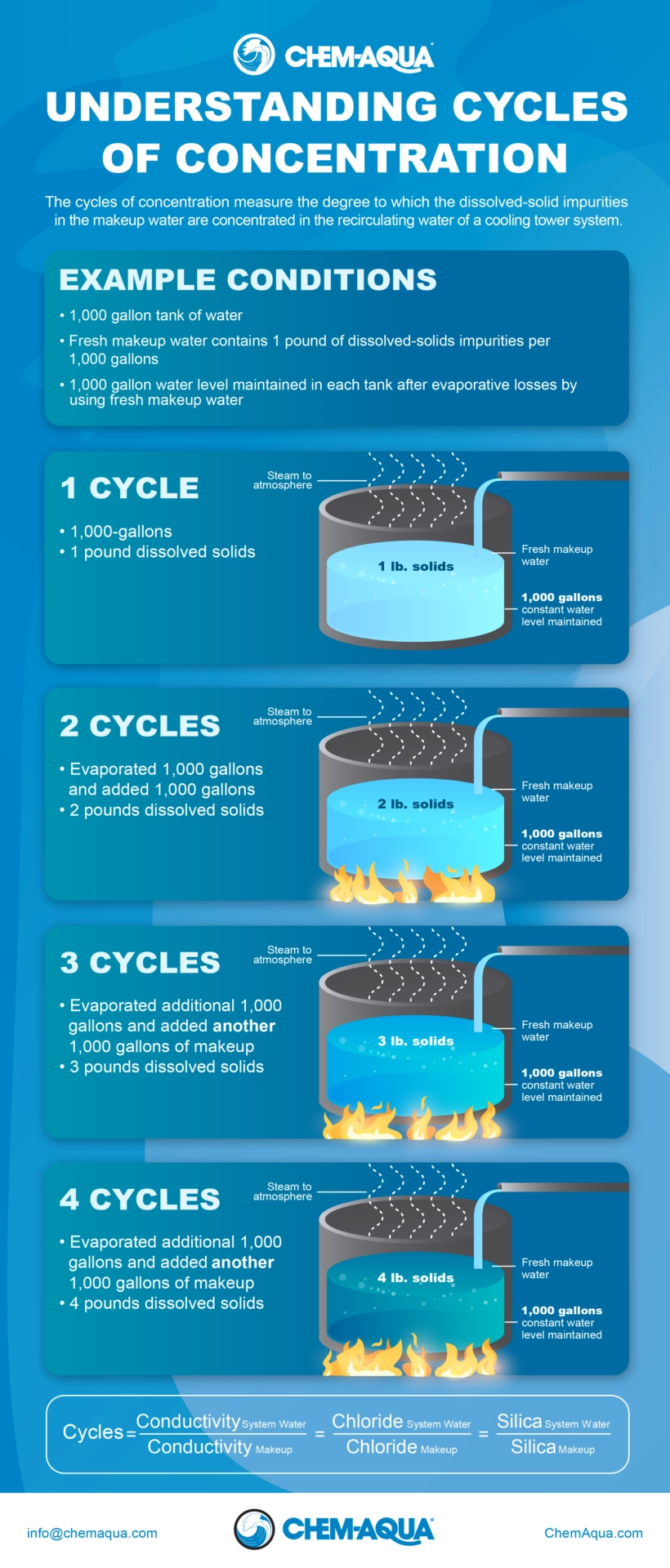

Understanding Cycles of Concentration

A Closer Look

Evaporative systems are more complex to treat than closed systems. Why? It’s because the solid impurities become increasingly concentrated in the system water during the normal course of operation. Makeup impurities do not typically concentrate in closed systems. In evaporative systems, large quantities of water are used on an ongoing basis. Economics dictate the use of chemicals that can be applied at low dosages. Closed systems normally use only the amount of water required to fill the system one time and any water losses from leaks and repairs.

A Key Concept in Boiler and Cooling Water Treatment

“Cycles of concentration” is one of the most important concepts in boiler and cooling water treatment. It measures the degree to which the solid impurities in the makeup water are concentrated in the recirculating water of an evaporative system. The higher this ratio, the more the impurities in the makeup water are being concentrated in the system water. It can be estimated by dividing the conductivity of the system water by the conductivity of the makeup, or by dividing the chloride of the system water by the chloride of the makeup.

How Cycles of Concentration Increase

Consider a pot of boiling water maintained at a constant level of 1,000 gallons by the addition of tap water. If the tap water used for makeup contains 1 lb. of solids in every 1,000 gallons, and initially the pot is filled with 1,000 gallons of tap water, the system water is said to be at 1 cycle. This is because no evaporation has occurred yet. If 1,000 gallons of water has been removed by boiling and 1,000 gallons of tap water was added to keep the level constant, there will be an additional 1 lb. of dissolved solids in the pot. As a result, the system is said to be at 2 cycles. The cycles of concentration increase by one for each system volume of water that is evaporated.

Bleed or Blowdown

If we keep evaporating water and adding more makeup water to maintain constant volume, the solids concentration and the cycles will keep increasing. Eventually, the water becomes saturated and precipitation reactions will occur between the dissolved solids in the water and scale deposits will form. To limit the concentration of dissolved solids and prevent problems, a portion of the concentrated system water must be discharged. This is called bleed in a cooling water system, and blowdown in a boiler.

For every evaporative system, there is a target cycles of concentration based on the makeup water quality, the design and operating conditions, and the treatment methods. To maintain the target cycles once reached, one pound of solids must be discharged through bleed for every pound of solids brought in with the makeup water. The following shows the relationship between the cycles, makeup, and bleed rate:

- To maintain 2 cycles, ½ the amount of makeup water added must be discharged as bleed

- To maintain 4 cycles, ¼ the amount of makeup water added must be discharged as bleed

Contact your water treatment experts at Chem-Aqua to maximize you water savings and cycles of concentration. Learn more by visiting chemaqua.com/en-us/About-Us/Who-We-Are.

Read more at chemaqua.com

Read more at chemaqua.com