Pioneering Medium Payload Automation: Unveiling KUKA’s KR IONTEC

In the evolving world of industrial automation, manufacturers grapple with the need for flexible, efficient, and future-proof solutions that can handle a diverse range of tasks without compromising performance. Enter KUKA’s groundbreaking solution – the KR IONTEC. This robot is setting new standards in the medium payload automation range and addressing manufacturing challenges with superior flexibility, sustainability, cost-efficiency, and performance.

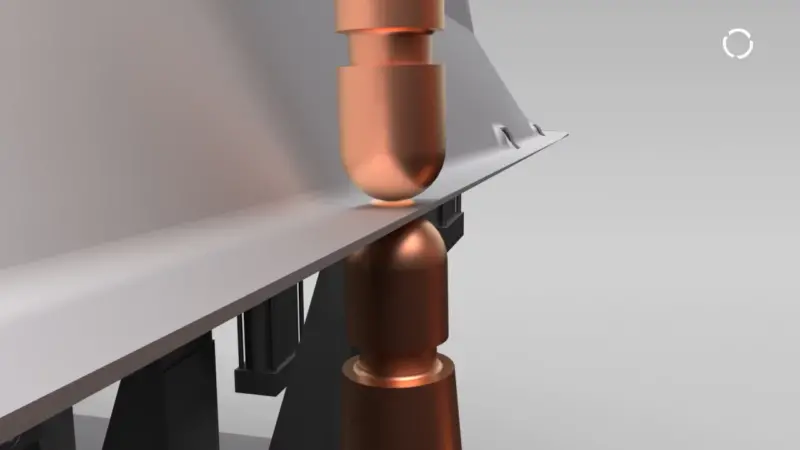

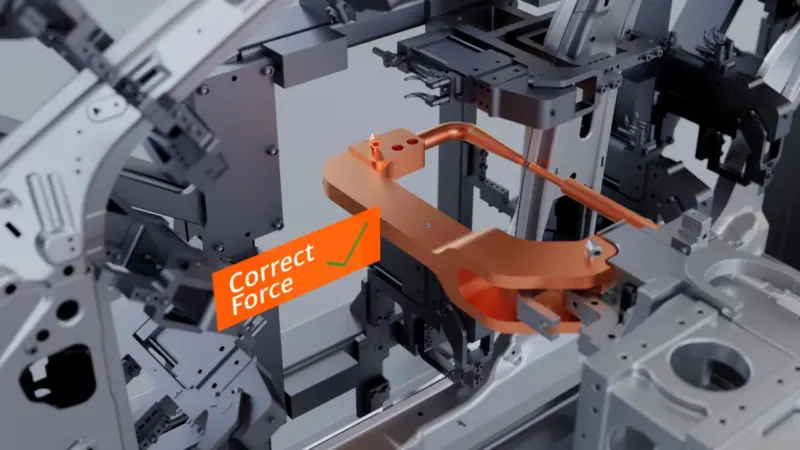

The KR IONTEC stands at the forefront of the 30 to 70 kilogram class, leading in areas such as work area, operating costs, and maintenance requirements. This adaptable robot can handle any task and mounting position – floor, wall, ceiling, incline – making it a truly versatile player in any manufacturing environment. It’s designed for a variety of motion processes, from path mode to performance mode to dynamic mode, offering exceptional performance tailored to diverse manufacturing requirements.

One of the distinguishing features of the KR IONTEC is its payload adaptability. The payload can be converted from 30 kilograms to 70 kilograms even while the robot is installed. This minimizes production interruption, thereby increasing operational efficiency and decreasing downtime.

But the KR IONTEC doesn’t stop at operational excellence. This robotic solution combines unmatched performance with a commitment to sustainability through low energy consumption. It enhances output while simultaneously reducing running costs, striking a balance between operational efficiency and environmental responsibility.

Future-proofing is central to the KR IONTEC design. It’s fully digitized and built to handle the production challenges of tomorrow, ensuring manufacturers can remain competitive in the face of rapid technological change.

In summary, the KR IONTEC is pioneering medium payload automation as it embodies best-in-class flexibility, sustainability, cost efficiency, and performance. This robot is an industry game-changer, offering manufacturers a robust and versatile solution to a myriad of medium payload challenges. For more information on how the KR IONTEC can revolutionize your manufacturing processes, contact KUKA today.

To learn more about what KUKA is up to, check out the show, Orange Intelligenz.