Optimizing Welding Quality with KUKA.EqualizingTech: The Future of Industrial Manufacturing

For manufacturers, achieving consistently high welding quality is a complex problem. Any slight misalignment or miscalculation in force can lead to bending of sheet metal, inaccurate welding force, and ultimately, defective welds. Traditional welding guns use mechanical equalizing systems to combat these issues, but this solution isn’t without its drawbacks. These systems are often complicated, heavy, and costly to maintain. Manufacturers need a more innovative, cost-effective solution, and KUKA has the answer with their EqualizingTech.

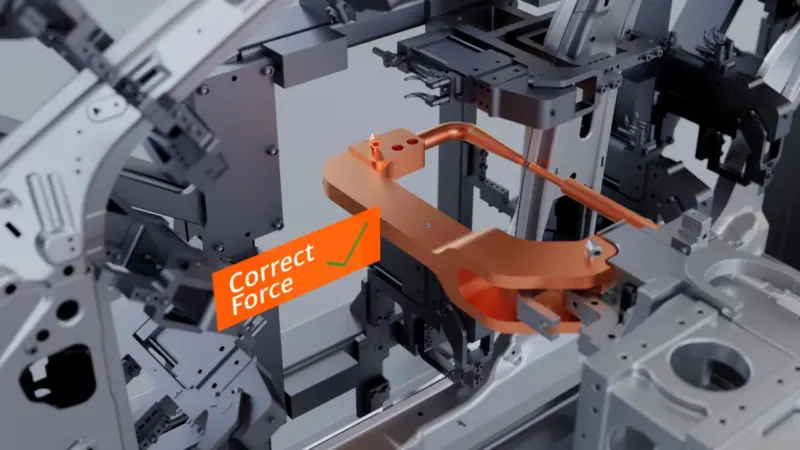

KUKA.EqualizingTech is an additional function of KUKA’s spot welding software designed to dramatically improve welding quality and force accuracy. It saves weight and costs typically associated with mechanical equalizing systems. Instead of relying on mechanical components, KUKA.EqualizingTech substitutes these with robot motion, actively guiding the robot to the appropriate welding position. This innovative approach reduces force on the part being welded, mitigating the bending issue and ensuring an accurate welding force.

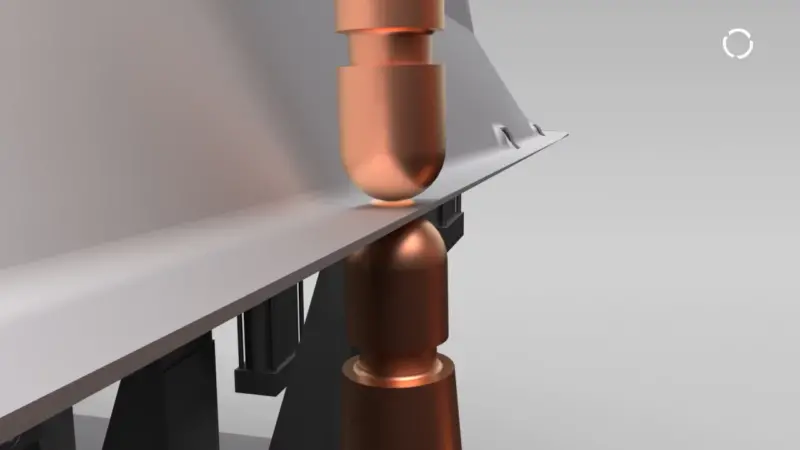

The process with KUKA.EqualizingTech is systematic. The weld spot is first approached, and equalization is activated. The stationary tip then moves partially towards the sheet metal, while a parallel closing motion brings the electrodes together. The stationary electrode finally moves through the robot, resulting in an equalizing motion that prevents the sheet metal from bending. Thus, the correct welding force is guaranteed.

KUKA.EqualizingTech also offers a high degree of flexibility. Its behavior can be configured to be weak, medium, or strong based on part flexibility or stiffness. Equalization can also be switched off or set to user-defined parameter sets on each weld location, providing unparalleled customization.

What sets KUKA.EqualizingTech apart from traditional mechanical systems is the fact that it requires no mechanical or pneumatic components. This reduces weight on a typical gun by 10-15%, which could even enable the use of a smaller robot. The lack of electrical controls, sensors, or compressed air infrastructure significantly lowers investment costs, wear, spare part requirements, and maintenance effort.

By embracing KUKA.EqualizingTech, manufacturers can achieve better, more reliable welding results while simultaneously reducing equipment and follow-up costs. This innovation represents a significant step forward in industrial manufacturing, highlighting the powerful role automation and advanced robotics can play in solving traditional manufacturing challenges.

KUKA.EqualizingTech isn’t just an add-on; it’s a game-changer. It is leading the way in the industrial revolution, redefining expectations for welding quality and cost-effectiveness. Manufacturers keen to stay competitive and optimize their processes must look to solutions like KUKA.EqualizingTech as the new standard. To learn more, contact KUKA today and check out Orange Intelligenz to discover the future of industrial manufacturing.