Revolutionizing Manufacturing: The Power of KUKA’s ServoGun Family For Spot Welding

In the high-speed and precision-demanding world of manufacturing, any slight error in spot welding can result in costly and time-consuming reworks, and even product recalls. Manufacturers are constantly challenged with maintaining consistent welding quality, dealing with hard-to-weld materials, minimizing maintenance costs, and preventing rapid welding tip wear. The ultimate solution to these problems lies not in traditional methods, but in the realm of advanced automation. Enter KUKA.ServoGun, an innovative solution transforming the future of spot welding. This episode of the show gives you an in-depth look at what KUKA offers with this solution.

KUKA.ServoGun is more than just software; it’s an entire family of application modules designed to evolve a KUKA robot into a highly efficient spot welding machine. This solution addresses the pain points of the manufacturing industry by offering unrivaled accuracy, advanced technology, and a deep focus on cost-effectiveness.

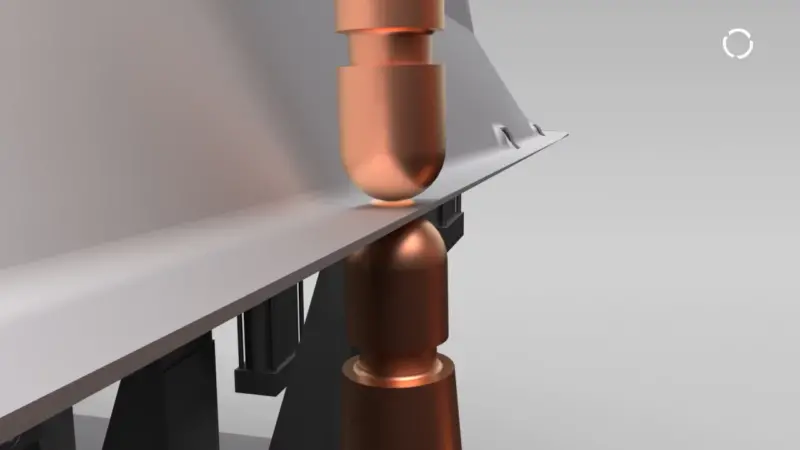

One of the standout members of this family is the ServoGunBasic module. By leveraging KUKA’s recent transition from torque control to calibrated position control, ServoGunBasic enables independence from tool aids, temperature, and orientation, guaranteeing a force accuracy of 3-7% of the welding force. Innovations like patented part detection, compensation for gun arm bending and shifting, and welding tip wear compensation are all a part of this ground-breaking package. An additional built-in configuration wizard and automatic force calibration process lead to substantial time and cost savings.

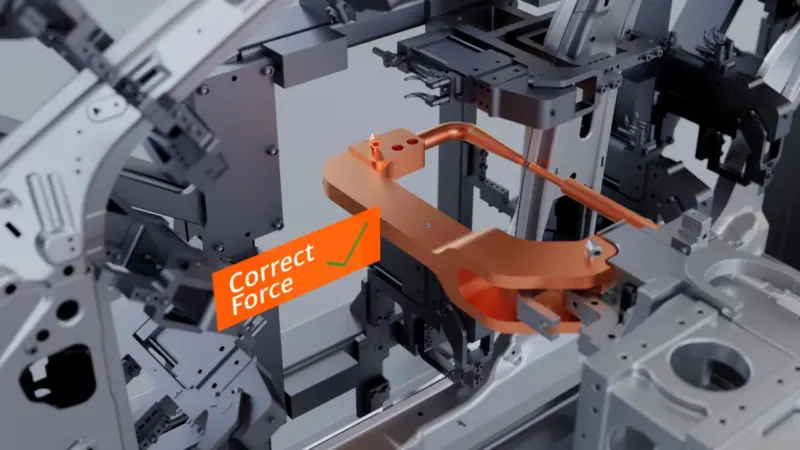

When it comes to hard-to-weld materials like aluminum, the ServoGunAdvanced module comes into play. With a built-in force sensor, this advanced technology readjusts the force during the welding process, ensuring a higher force accuracy of 1-3% of the welding force, a significant improvement over conventional welding methods.

Moreover, the Equalizing Tech module compensates for force inaccuracies due to part mispositioning without the need for costly pneumatic equalizing mechanisms. Lastly, the RoboSpin module enables aluminum spot welding and prolongs the life of welding tips by rotating electrode tips during the welding process, requiring no additional hardware or special integration.

These modules, when combined, have the potential to significantly decrease initial investments, maintenance efforts, and subsequent costs for manufacturers. Ensuring high-quality welds, they’re already deployed with about 35,000 spot welding robots globally.

KUKA.ServoGun is not just a tool for manufacturers; it is a solution to many of their significant challenges. By enabling precision, reducing costs, and promoting efficiency, it heralds a new era in industrial automation and manufacturing.

The time is now for manufacturers to embrace these advanced solutions and lead the way in the industrial revolution. With KUKA.ServoGun, they can improve their processes, enhance product quality, and secure a strong position in the future of manufacturing.