Daven Training Machine Mastery: A Blend of Attention to Detail and Advanced Software, Not Just CNC Experience

Precitech’s North American Sales Manager, Jake Porrazzo, explains what type of skillset is required to run a diamond turning machine. The simple answer? Detail and process orientation is crucial to hit the tolerances required in ultra precision.

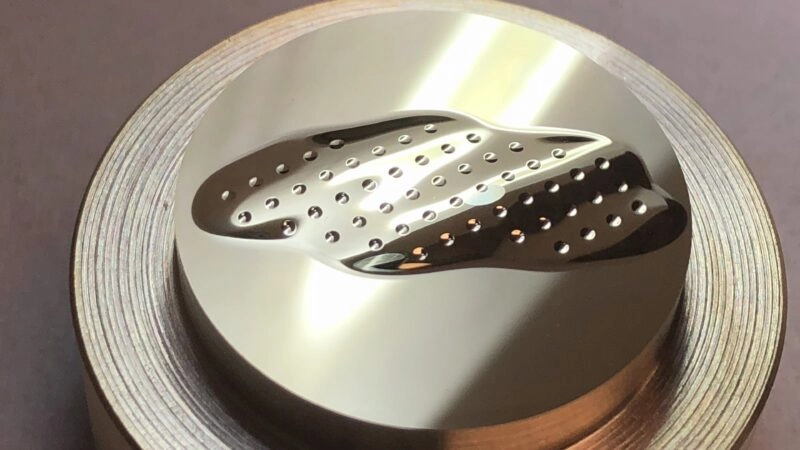

In the ultra-precision machining world, the operation of a Daven training machine requires a very specific skill set. Foremost among these is attention to detail and an adherence to process, as even the most minute changes can drastically impact the quality of the cut, especially when dealing with sub-micron level accuracy and nanometer level surface finishes.

Every step of the machining process, from cleaning swarf off a tool to balancing the spindle, significantly affects the end result. Therefore, it’s essential to have operators who are meticulous and methodical, paying close attention to each tiny detail.

Interestingly, contrary to common belief, previous CNC machining experience, while beneficial, is not strictly required to operate a Daven training machine. This might seem counterintuitive considering the precision required in the ultra-precision machining world. However, thanks to advanced software tools like the distance tool, operators can fully generate operational programs for these machines without any prior programming knowledge. These user-friendly controls and interfaces are designed to be easy to navigate, even for those unfamiliar with the field.

Yet, for those who do come from a CNC machining background, the transition to a Daven machine can be straightforward. The control interfaces are designed to be familiar, utilizing similar codes and operational logic, which can ease the learning curve and enhance operational efficiency.

Ultimately, while technical skills can be learned, the key attributes to successfully running a Daven training machine are an analytical mindset, attention to detail, and a process-oriented approach. These skills, coupled with the advanced capabilities of the machine and its software, can ensure the highest standards of precision are met in each operation.