Diamond Turning: The Evolution of Precision Optics Manufacturing Through Innovative Freeform Surfaces

Jeffrey Roblee, VP of Technology at Precitech, had a deep conversation with Savannah Jones about the history and advancements in diamond turning. Precitech, originally known as Newell Precision in the 1960s, is renowned for making bearings and bearing rotary stages. The company has significantly advanced precision motion, which is essential in the manufacture of optics through diamond machining.

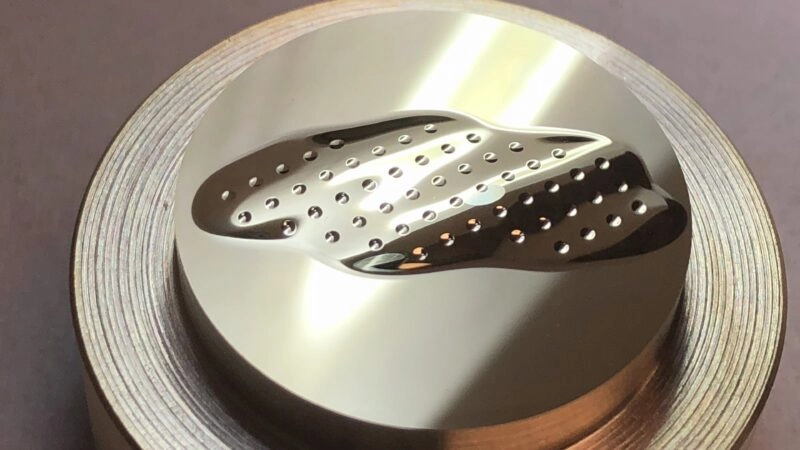

Jeff explained how diamond tools have unique properties allowing them to create an optical surface on a variety of materials, including non-ferrous metals and different plastic and synthetic materials. The advent of diamond turning led to the acceptance of asymmetric optics. Precitech focused on taking these building blocks of precision motion control and applying them to making optics.

Roblee’s career has been tightly intertwined with the evolution of diamond turning since his early days at Lawrence Livermore National Laboratory (LLNL) in the late 1970s. He then spent some time at Carl Zeiss in Germany and later moved to Polaroid, both also utilizing diamond turning. He joined Precitech in 2002 and has been instrumental in pushing the boundaries of the technology.

The conversation took a trip back in time to the early days of diamond turning, starting from simple two-axis machining to the introduction of fast tool servos and zc (slow tool servo) turning, enabling the creation of freeform surfaces. The advent of single point diamond turning, now the preferred method, offered more control and precision.

The industry’s progression has led to the increased use of freeform shapes and an extra degree of freedom for optical designers. Advancements have allowed designers to improve the performance of optical systems or make them more compact. Today, freeform surfaces that don’t have an axis of symmetry have become a growing need, enabling the creation of complex shapes that couldn’t be achieved by traditional optics manufacturing.

Finally, they discussed the future, foreseeing processes becoming simpler and more streamlined. The cost of making molds or optics directly for freeform surfaces is decreasing, making it more manageable. Precitech has made strides in this area, creating a machine with a vertical linear axis and two horizontal axes.

Overall, the conversation shed light on the evolution of diamond turning technology, its impact on the optics industry, and the exciting prospects for the future.