Single-Point Diamond Turning Revolutionizes Optics Manufacturing

Jeff Roblee, Vice President of Technology at Precitech, elucidates on the transformative role of diamond turning in the optics manufacturing industry. According to him, the advent of precision motion control, which is a vital aspect of Precitech’s technologies, has revolutionized the creation of finished optics.

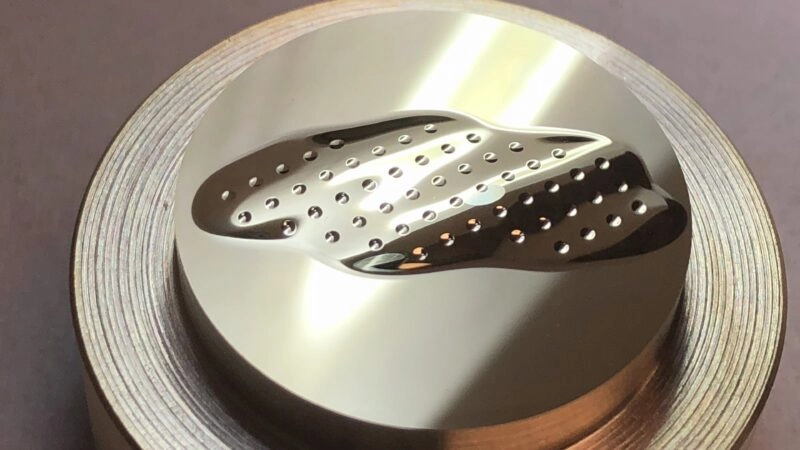

Diamond turning enables the accurate positioning of a diamond tool and a high-speed spinning workpiece, facilitating the machining of material to create an optic that does not necessitate any further polishing. Diamond turning, with its myriad tool shapes, allows for the creation of structured and unconventional surfaces that traditional optics manufacturing methods could not achieve.

Roblee highlights that the onset of diamond turning has greatly encouraged the acceptance of aspherical optics in the industry. He recalls the rarity of designing aspherical optics at the start of his career in the early seventies. With diamond turning, aspherical optics could be created as readily as spherical ones. This technology has since evolved to accommodate even more intricate shapes.

The application of precision motion control, a core building block of Precitech since the 1960s, to optics creation continues to be their primary focus today. They’ve also diversified this technology into the Sterling product line for producing ophthalmic lenses, embodying the same fundamental positioning of a tool with respect to the workpiece. This speaks to the expansive influence of diamond turning technology and its potential for continual advancement in the field of optics manufacturing.