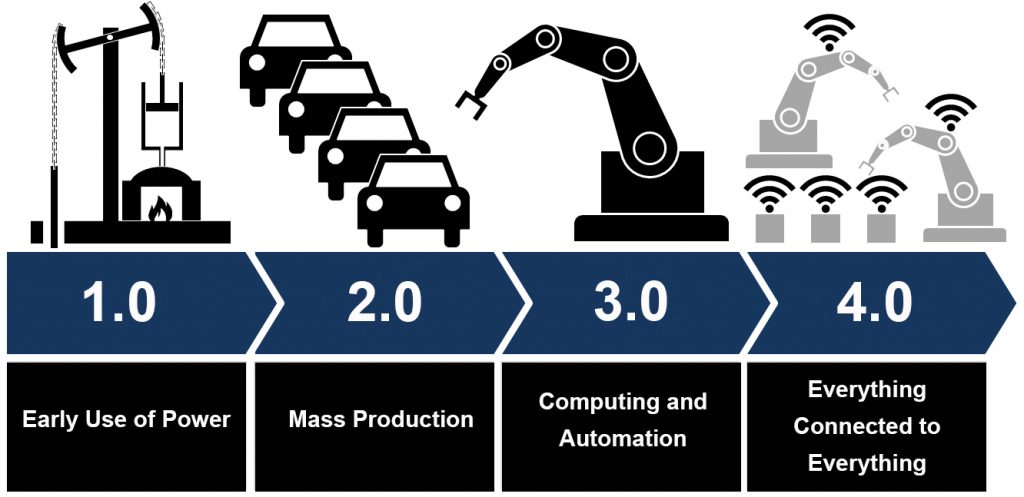

Recent technological advances such as the Internet of things (IoT), cloud computing, and artificial and augmented intelligence (AI) have created a lot of hype in building construction. These cyber-physical systems are being categorized under the collective term “Industry 4.0”—an environment in which everything is connected, from simple machines all the way up to complex computing systems.

Unfortunately, construction, including the building construction sector, has lagged behind other industries in adopting advanced technology. It’s only been about a decade or so since construction began moving from building everything in the field to taking advantage of mass production for modular pieces such as bathroom pods and headwalls involving multiple trades. This means the industry – especially in the field – remains largely stuck at Industry 1.0.

As industry leadership passes to a new generation of executives who are more technologically savvy and recognize the opportunities of digitalization, many firms are rushing to play catchup by attempting to adopt mass production (Industry 2.0), computer automation (Industry 3.0) and IoT/AI (Industry 4.0) all at the same time in an approach that could be considered “triple innovation.” The rewards for success are great, but there is a significant danger in rushing ahead.

The Benefits and Risks of ‘Triple Innovation’

Investing in the latest technologies – such as laser scanning, connected devices and even mixed reality experiences – is critical to squeezing incremental productivity out of each precious work hour while driving down risk by reducing and even eliminating rework. State-of-the-art sensing technologies allow full transparency into existing conditions and site progress, and innovative positioning technologies provide precise navigation so that systems built off-site can be conveyed and placed correctly. As we step into the future, embracing even more advanced technology will allow building construction firms to attract the best and brightest talent to the industry by making it a high-tech, attractive vocation.

However, such investments must be done with a solid understanding of how to best scale the learning curve and transition seamlessly from manual to digital construction methods. The FMI Corporation, in a causal analysis of large contractor bankruptcies, found a lack of an innovation process – leading to too much change too quickly and non-strategically – to be an indicator of the downfall of firms. Innovation is absolutely essential to maintaining a competitive position locally and globally, but it must occur within a carefully constructed strategic framework.

The Advantage of a Powerful Alliance

For many firms, the key to building the right strategy is leveraging a partnership approach between technology user and technology manufacturer — one in which the user’s needs drive continuous innovation in technology, and the user can rely on expert guidance from the manufacturer.

The most powerful alliances both educate and enable the current and future workforce. Working together, the manufacturer and user create a seamless connection between the virtual and the physical throughout the project lifecycle.

As increased digitalization in the office through virtual design and construction (VDC) and building information modeling (BIM) continues to lay the groundwork for the rapid adoption of digital technologies in the field, building construction firms have the opportunity to gain new levels of productivity and profitability by making the leap to Industry 4.0. Working with the right technology provider is a surefire strategy to achieve success.

Explore how Leica Geosystems empowers digital transformation in building construction at https://leica-geosystems.com/en-us/industries/building/commercial.

Read more at http://bimlearningcenter.com