Mastering Precision in Spot Welding Operations: KUKA.ServoGunBasic Streamlines Manufacturing

Industrial manufacturers face a myriad of challenges, with one of the most critical being achieving consistent, high-quality spot welding. Factors such as gun positioning, weld force, and dynamic gun compensation directly impact the quality and integrity of the welds. Manufacturers have long depended on standard torque-controlled guns, which use motor current to reach the target force. However, these tools’ efficacy is influenced by temperature, age, and gun position, often leading to discrepancies between target and actual welding force. This reality calls for a more advanced, reliable solution, and KUKA has risen to the challenge with KUKA.ServoGunBasic. On this episode of the show, we learn more about this innovative solution and how it can help spot welding operations.

KUKA.ServoGunBasic is a specialized application software designed for any spot welding gun with electric servo motors. The technology specifically addresses the many complexities manufacturers face, delivering enhanced precision and reliability in spot welding operations.

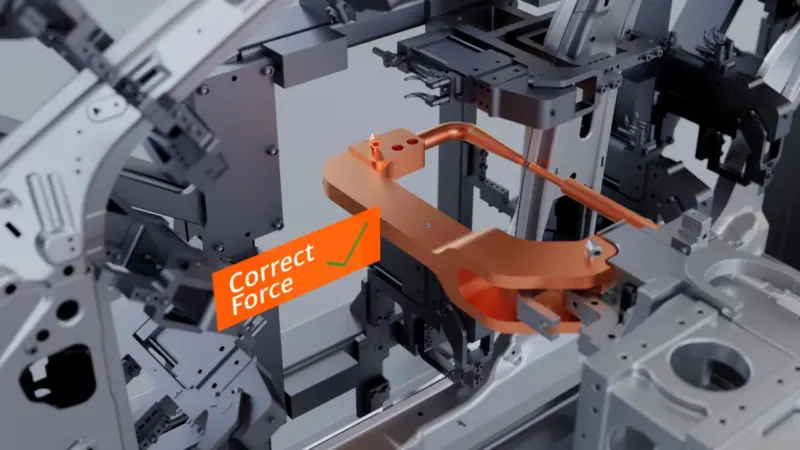

In the heart of KUKA.ServoGunBasic lies an innovative control principle, transitioning from torque control to calibrated position control. This shift significantly improves accuracy, ensuring that discrepancies are reduced to just 3-7% of the target workforce compared to the traditional 10-15% deviation.

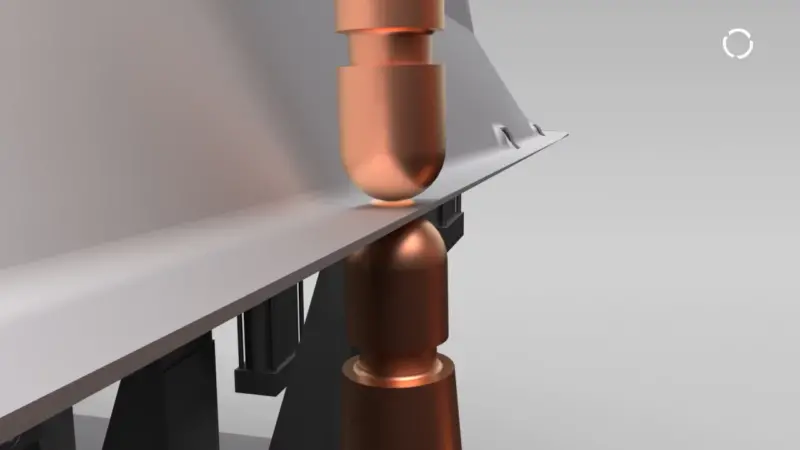

The method to achieve this is a two-stage force build-up process. The first step leverages a patented part detection capability to determine the sheet. The second step commands the gun to move to a pre-calibrated position to achieve the welding force. The motor’s movement now serves as the nominal variable instead of the current, enabling high repeatable welding quality independent of tool age, wear, temperature, and orientation in space.

But KUKA.ServoGunBasic offers even more. Its feature set includes intelligent tip wear management, compensation for gun bending, and compensation for sliding effects upon pressuring on Xguns. These capabilities ensure the correct position of the electrode and the proper build-up of the welding force, thereby guaranteeing reliable, high-quality welding.

To support efficient operations, KUKA.ServoGunBasic also offers a built-in configuration wizard and automatic weld force calibration. These features save precious time during setup and commissioning.

KUKA.ServoGunBasic is not just a tool—it’s an enabler of excellence in industrial manufacturing. It brings easy and fast integration, efficient troubleshooting, and compatibility with virtually any spot welding gun and servo motor that complies with KUKA’s specifications. It empowers manufacturers to achieve consistently perfect welds in a cost-effective and efficient way.

With KUKA.ServoGunBasic, manufacturers can shift away from traditional, less efficient methods and embrace a future marked by unparalleled precision and consistency in spot welding. KUKA.ServoGunBasic is redefining the standards of industrial manufacturing, leading the way in the revolution of precision automation. To learn more, contact KUKA today and discover how KUKA.ServoGunBasic can revolutionize your welding operations.