Transforming Aluminum Resistance Welding: Introducing KUKA.RoboSpin

In manufacturing, the complexity and challenges of welding aluminum components have long been a roadblock. Aluminum’s inherent properties, including surface oxidation and the propensity to build up caps, interfere with welding quality and efficiency. This not only increases time and cost but also shortens the lifespan of welding tips. KUKA, an industrial automation pioneer, has devised a game-changing solution to these longstanding problems: KUKA.RoboSpin that can transforming aluminum resistance welding:

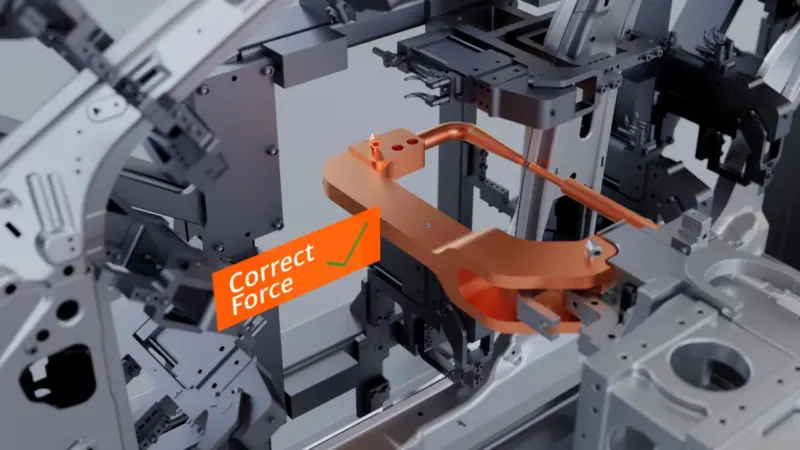

KUKA.RoboSpin is an innovative add-on package for the KUKA servo gun software solution. Its function is to improve spot welding on aluminum components through the execution of a rotational motion about the tool center point. This breakthrough technology prevents the adherence of tips to the metal, resulting in enhanced weld quality, longer tip life, more efficient resource use, and significant savings.

In traditional aluminum resistance welding, the oxidation layer on the surface heightens resistance, impeding the current flow from reaching the weld joint where it is needed most. This, coupled with the aluminum cap build-up, necessitates frequent tip dressing, further compromising quality and adding to both time and cost.

KUKA.RoboSpin, with an active patent, offers a thoroughly tested and well-developed solution to overcome these challenges. By executing a mechanical rotation during the weld sequence, the weld tips scratch through the oxidation layer, allowing current to travel more efficiently to the joint.

Compared to conventional methods, KUKA.RoboSpin offers up to ten times more cap life and reduces the number of tip changes by one to two per shift, significantly enhancing overall weld quality. The innovative technology contributes to less disruption to the surface condition, lower contact resistance, and a more consistent spot weld diameter. The constant rotating condition ensures less heat in tips, leading to a longer tip lifetime, and facilitates the welding of conventionally non-weldable materials and coatings.

A notable bonus of KUKA.RoboSpin is its aesthetic impact: the spot weld appears polished rather than welded, reducing potential needs for additional work before applying paint.

In summary, KUKA.RoboSpin offers an impressive, well-designed answer to the challenges of aluminum resistance welding. Its innovative approach enhances efficiency, increases savings, and ensures the production of high-quality welds. For those eager to meet the challenges of aluminum resistance welding head-on, KUKA.RoboSpin is your game-changing solution. To find out more, contact KUKA today and check out the show, Orange Intelligenz.