Unleashing the Future of Automotive Manufacturing with KUKA.ServoGunAdvanced

In today’s advanced automotive manufacturing landscape, the emphasis on the use of lightweight materials such as high-strength steel grades, aluminum, and aluminum alloys has never been greater. As industries evolve, they necessitate the development of innovative technologies to ensure the highest quality spot welds, given these materials require a high degree of force accuracy. For manufacturers, the challenge lies not only in meeting these complex requirements but doing so while improving efficiency, reducing costs, and ensuring flexibility. The solution? KUKA.ServoGunAdvanced.

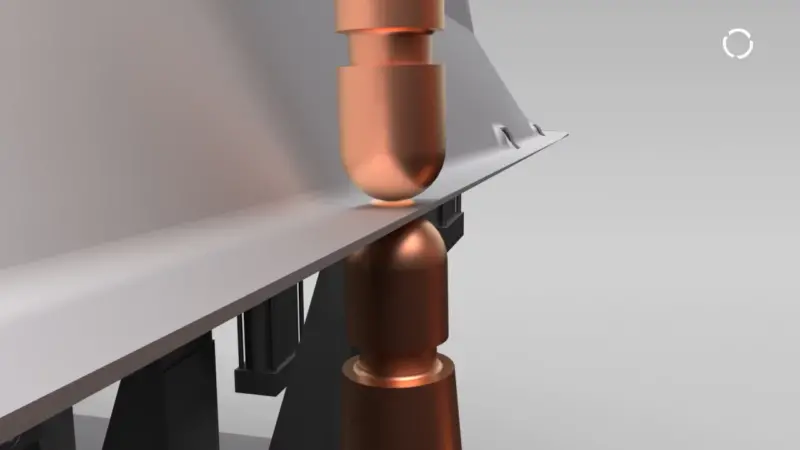

Recognized as a champion in welding applications, KUKA has once again set the benchmark for high-performance spot welding with its premier ServoGun Advanced software. KUKA.ServoGunAdvanced goes beyond conventional systems by integrating a force sensor that continuously measures and regulates the applied force throughout the entire welding process. This unique technology ensures an unmatched deviation of only one to three percent from the target welding force.

The adaptability of KUKA.ServoGunAdvanced stands out in a fluctuating production environment. It adjusts the welding force in real-time to counteract any changes in conditions, thereby preventing faulty welds caused by welding electrode tips sinking into the material and losing force. This feature becomes pivotal when working with different materials or multiple sheets, where maintaining a consistent welding force is paramount to achieving high-quality results.

With KUKA.ServoGunAdvanced, users can configure the welding force according to a predetermined force profile, making the welding process not just more efficient, but also independent of external influences like mechanical wear, age, the orientation in space, and the temperature of the welding gun. Such capabilities eliminate the need for periodic system calibration, offering a more streamlined production process.

KUKA.ServoGunAdvanced is not only about advanced functionality but also about practicality and cost efficiency. Traditionally, force regulation in welding required special servo motors with integrated force sensors. KUKA.ServoGunAdvanced revolutionizes this approach by enabling the use of any type of welding gun and servo motor, provided a validated external force sensor is installed on the welding gun. This innovation reduces investment costs significantly and injects unparalleled flexibility into the system.

Integration is also straightforward with the preconfigured interface, highlighting KUKA’s commitment to user-friendly design and easy adoption. KUKA.ServoGunAdvanced has already proven its mettle in thousands of industrial applications worldwide, significantly improving weld quality, enhancing the weldability of hard-to-weld materials, and reducing time-consuming inspections and rework.

Experience the benefits of this pioneering technology in your production systems. With KUKA.ServoGunAdvanced, the future of automotive manufacturing is already here. Contact KUKA today and unlock the full potential of your production line with the power of Industrial Intelligence and learn more about what KUKA is up to, check out the show.