How to Choose the Right 3D Printing Material

Learning to successfully execute a 3D printing project opens doors to new efficiencies, repeatability and innovation – but it’s not as simple as hitting start and hoping for a clean print.

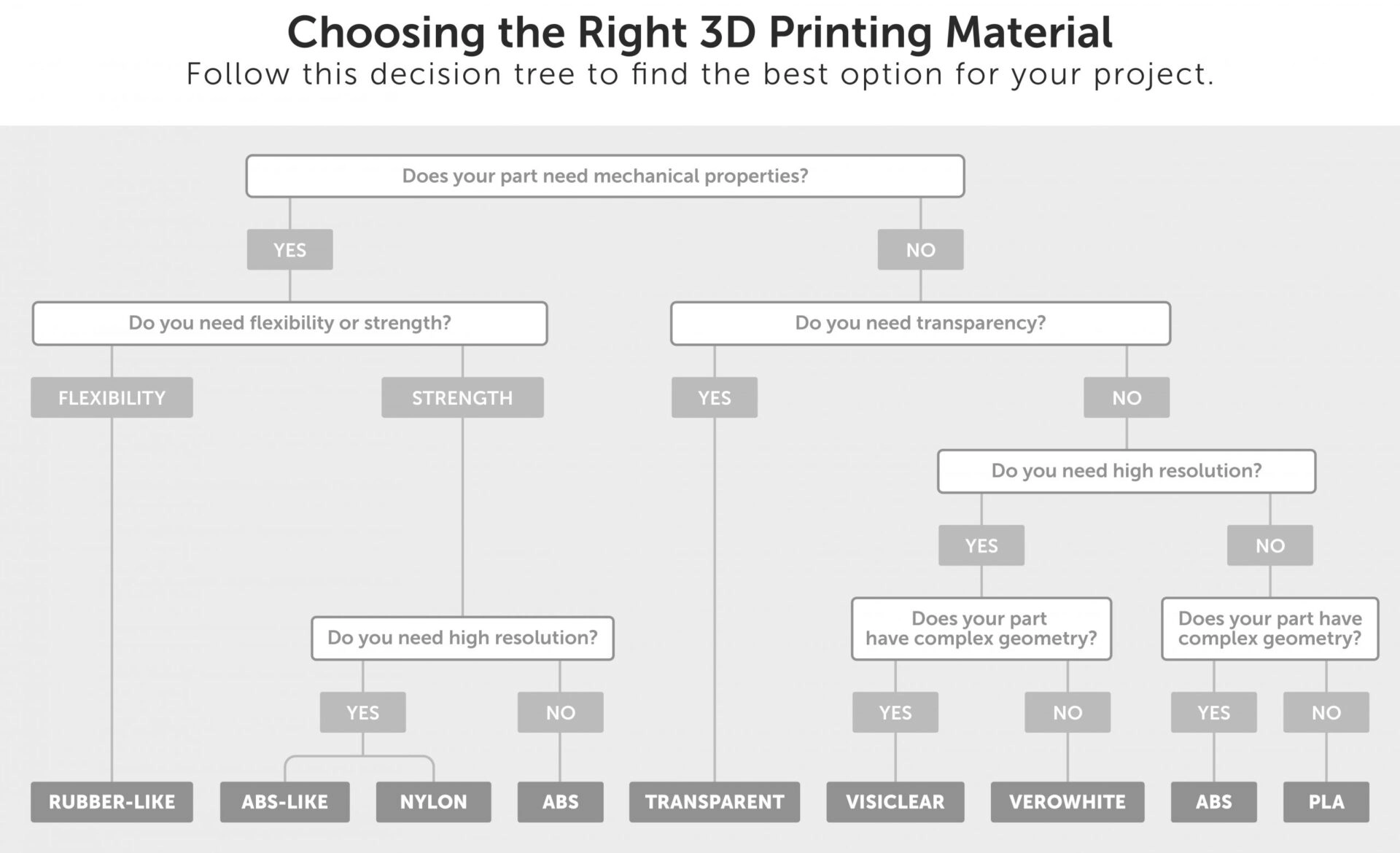

When you’re ready to start a new 3D printing project, you have to address one core dilemma – what will you actually print the project with? Material selection is key, and there are a number of variables that determine the material you choose.

Since some printing materials can print more than one type of object, these decisions can get tricky. Fortunately, there are specific questions you can ask to narrow down the field and help you pick the right material for every unique project.

Does Your Project Have Mechanical Properties?

This is the first and most important question to ask when determining which material to use for your 3D printing project. Mechanical properties help a product respond to physical forces exerted upon it, and the finished result may need to hold up to differing amounts of those forces.

For example, does your finished product or part need to be flexible, so it can bend when used? Does it need to be durable and strong, so it can withstand repeated use?

For printing purposes, you’ll want to determine whether your product requires flexibility or strength as its primary mechanical property.

Objects that Need To Be Flexible

Whenever you’re printing something that must be able to flex and bend during use, you immediately limit your choices to rubber-like printing materials.

These materials are the only ones that will give your product the flex required to bend when being used. Anything else will produce a product that is far too solid for your part to work properly.

Objects that Need To Be Strong

3D-printed products that need to be strong enough to endure heavy use and force will require printing filament that provides excellent strength capacity.

These include ABS, ABS-like, and nylon printing materials. Choosing the one you need is simply a matter of asking one more question – does your object need to be printed in high resolution?

Objects with High-Resolution

Projects that require a significant amount of strength and durability alongside high-resolution printing can be printed with two materials – ABS-like and nylon. Both of these options provide excellent strength and will work extremely well when leveraged in high-res settings.

Objects without High-Resolution

Products that can be printed outside of a high-res setting are best when printed with ABS.

—

Click here to learn more about how Fictiv can support your unique 3D printing needs.