60 Years of Precision

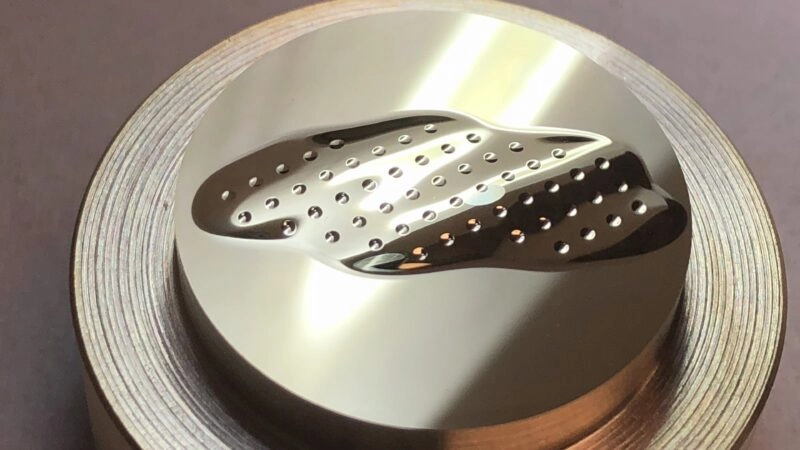

Precitech designs and manufactures ultra precision machining solutions for freeform diamond turning, milling, and grinding which are used to produce optical lenses, mold inserts, mirrors, and precision mechanical components. Our diamond turning machines produce rotationally symmetric, asymmetric, freeform, and sculpted geometries with form tolerances in the sub-micron range and nanometer surface finishes.

Precitech

Introducing Stacis 4, the next generation in active floor vibration control

Stacis is the leading floor vibration isolation technology worldwide, with a unique control system and serial architecture. It enables and protects electron and ion beam tools and other highly sensitive instruments from low-frequency vibration down to point three five hertz. The typical installation of Stacis 4 is as part of a quiet island consisting…

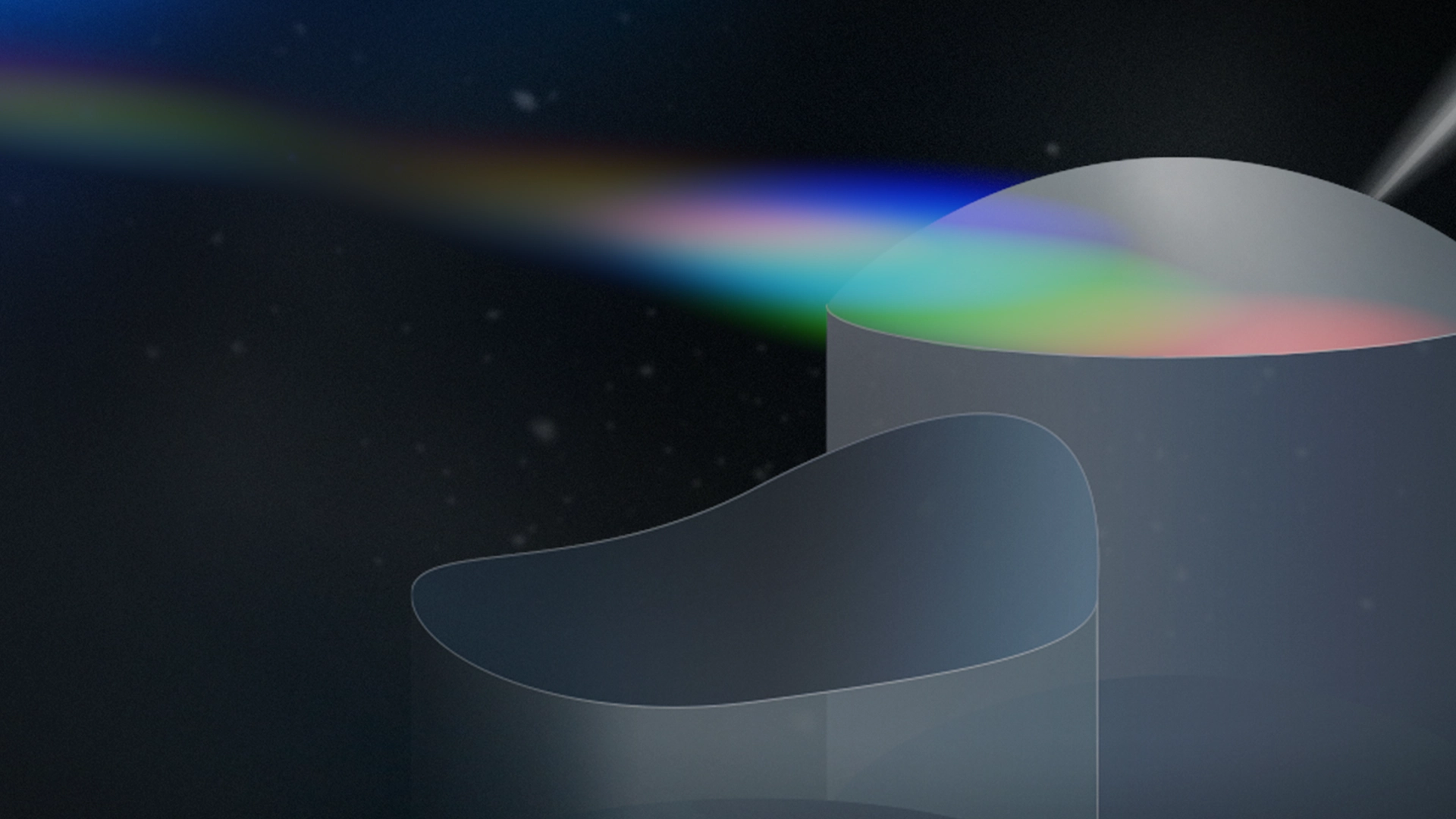

Freeform X: The Compact, 5-Axis Machine Revolutionizing Optical Component Manufacturing

The Freeform X, a cutting-edge product from Precitech, represents a significant breakthrough in the field of optical component manufacturing. Designed as a compact, 5-axis, single-point diamond turning machine, the Freeform X is an instrumental response to the industry’s need for crafting complex optical components, integral for products like reality-based headwear and next-generation mobile devices. The…

FTSE 5,000 Sets New Standards in Rapid and Accurate Production of Complex Freeform Surfaces

Precitech’s Fast Tool Servo (FTS) 5,000 emerges as an indispensable asset for advancing the production of complex freeform surfaces. With a maximum acceleration of 40 Gs and an ability to continuously follow a 25g path, this innovative tool serves as a keystone in rapid and precise part production, translating into significant time and cost benefits…

Single-Point Diamond Turning Revolutionizes Optics Manufacturing

Jeff Roblee, Vice President of Technology at Precitech, elucidates on the transformative role of diamond turning in the optics manufacturing industry. According to him, the advent of precision motion control, which is a vital aspect of Precitech’s technologies, has revolutionized the creation of finished optics. Diamond turning enables the accurate positioning of a diamond tool…

Introducing Stacis 4, the next generation in active floor vibration control

Stacis is the leading floor vibration isolation technology worldwide, with a unique control system and serial architecture. It enables and protects electron and ion beam tools and other highly sensitive instruments from low-frequency vibration down to point three five hertz. The typical installation of Stacis 4 is as part of a quiet island consisting…

Freeform X: The Compact, 5-Axis Machine Revolutionizing Optical Component Manufacturing

The Freeform X, a cutting-edge product from Precitech, represents a significant breakthrough in the field of optical component manufacturing. Designed as a compact, 5-axis, single-point diamond turning machine, the Freeform X is an instrumental response to the industry’s need for crafting complex optical components, integral for products like reality-based headwear and next-generation mobile devices. The…

FTSE 5,000 Sets New Standards in Rapid and Accurate Production of Complex Freeform Surfaces

Precitech’s Fast Tool Servo (FTS) 5,000 emerges as an indispensable asset for advancing the production of complex freeform surfaces. With a maximum acceleration of 40 Gs and an ability to continuously follow a 25g path, this innovative tool serves as a keystone in rapid and precise part production, translating into significant time and cost benefits…

Single-Point Diamond Turning Revolutionizes Optics Manufacturing

Jeff Roblee, Vice President of Technology at Precitech, elucidates on the transformative role of diamond turning in the optics manufacturing industry. According to him, the advent of precision motion control, which is a vital aspect of Precitech’s technologies, has revolutionized the creation of finished optics. Diamond turning enables the accurate positioning of a diamond tool…

Diverse Role Opportunities Spur Employee Growth and Foster a Unique Family-Like Environment

Working in an environment that promotes growth and encourages diverse roles can offer enormous benefits, particularly to someone starting a new career or eager to expand their skill set. According to a member of the Precitech team, this flexibility can provide exposure to high-tech manufacturing, metrology, and testing, while offering opportunities to work in different…

Precitech’s Factory in Keene: A Global Hub for Innovation in Single-Point Diamond Turning

As a hub of technological innovation and precision manufacturing, Precitech’s factory in Keene, New Hampshire stands as a testament to the company’s commitment to excellence in single-point diamond turning. Staffed by a dedicated team of around 100 highly skilled individuals, this facility is at the forefront of crafting high-precision products that set industry standards. Located…

Diamond Turning: The Evolution of Precision Optics Manufacturing Through Innovative Freeform Surfaces

Jeffrey Roblee, VP of Technology at Precitech, had a deep conversation with Savannah Jones about the history and advancements in diamond turning. Precitech, originally known as Newell Precision in the 1960s, is renowned for making bearings and bearing rotary stages. The company has significantly advanced precision motion, which is essential in the manufacture of optics…

Fast Tool Servo Offers Unprecedented Speed and Precision in Optics Manufacturing

In the world of diamond turning, a rapidly growing area of interest is the Fast Tool Servo (FTS). An often misunderstood component, the FTS is an essential accessory that helps enable precision machining, especially in the creation of non-rotationally symmetric freeform surfaces. By nature, freeform surfaces demand that the diamond tool follow their contours closely…

Daven Training Machine Mastery: A Blend of Attention to Detail and Advanced Software, Not Just CNC Experience

Precitech’s North American Sales Manager, Jake Porrazzo, explains what type of skillset is required to run a diamond turning machine. The simple answer? Detail and process orientation is crucial to hit the tolerances required in ultra precision. In the ultra-precision machining world, the operation of a Daven training machine requires a very specific skill set….