Innovative products and solutions for the life science industry's critical manufacturing environments

Welcome to Benchmark Products, the leading supplier of innovative solutions and products for life science manufacturers. With ISO 9001:2015 certification and cutting-edge ISO Class 7 Cleanroom facilities, we ensure exceptional quality. Over 500 customers trust us for custom kitting, fluid handling assemblies, product irradiation, and sterile quality assurance.

MarketScale

Benchmark Product Videos

BioMark Bags™: FDA-Compliant and Customizable Bioprocessing Bags for Secure Fluid Handling

In the demanding world of pharmaceuticals and life sciences, precision and compliance are critical. Benchmark Products leads the industry by providing high-quality, regulatory-compliant cleanroom solutions. Among those is it’s BioMark Bags™. These single-use bioprocessing bags tailored for the pharmaceutical industry, feature Renolit 9101 film for durability and chemical resistance. The bags have a 5-layer structure, offering…

The Bullard Sightline Hood

The Bullard™ Sightline Hood, crafted with Tychem® 2000 material, promises unparalleled comfort and productivity for users in manufacturing suites. Its design boasts features like a sleek profile, a panoramic 320-degree lens, effortless breathing, and a lightweight custom-fit hose that reduces head pressure. Enhanced with a roomy interior, soft sport knit neck cuff, and compatibility…

Benchmark GMP Cleanroom Socks

Benchmark GMP Cleanroom Socks are the ideal solution to keep manufacturing facilities Annex 1 compliant. These socks allow personnel to enter changing rooms leading directly to class B and class C cleanrooms. Additional features include: continuous filament polyester and nylon yarn particulate contamination reduction available in sizes S-2XL

Exceeding Your Benchmark

Pharma Manufacturing: Meeting Annex I with Precision Machining for Safer Sterile Drug Production

Pharmaceutical manufacturers are under increasing pressure to deliver sterile, high-quality medicines in smaller batches and faster cycles. As pharma manufacturing evolves, regulatory demands have intensified, especially following the 2023 revision of EU GMP Annex I, which places new emphasis on contamination control strategies, improved traceability, and minimizing human intervention throughout production. According to American…

Sterile Compounding and Contamination Control with Abby Roth

In this episode of Exceeding Your Benchmark, host Michelle Dawn Mooney speaks with Abby Roth, founder of Pure Microbiology, about sterile compounding and contamination control. Abby shares her expertise in microbiology, sterile environments, and best practices in pharmaceutical compounding. The conversation begins with a distinction between traditional drug manufacturing and sterile compounding, highlighting the…

One Year of The Exceeding Your Benchmark Podcast

Benchmark Products provides products for critical life science and pharma environments. In this podcast series Exceeding Your Benchmark, they interview leading experts on a variety of trending topics. In celebration of its first year, Exceeding Your Benchmark looks back at interviews with experts from life science and pharmaceutical manufacturing on timely topics from Annex…

Exploring the Fundamentals of Validation in Life Science Manufacturing

In the rapidly evolving domain of life science manufacturing, validation emerges as a cornerstone to ensure that products meet stipulated requirements concerning quality, safety, and efficacy. This pivotal aspect of manufacturing comes to focus as regulatory landscapes shift, mandating stringent compliance to ensure patient safety. In a recent episode of Exceeding Your Benchmark, a…

Pharmaceutical Manufacturing is Witnessing Major Transformation as New Demands for Sterility Assurance Reshape Healthcare

For an industry where precision and quality control are paramount, pharmaceutical manufacturing is witnessing an evolutionary leap in contamination control practices. Propelled by changes in regulatory environments, such as the EU’s Annex 1 update and ICH Q9 focusing on quality risk management, the sector is shifting from isolated, data-point-centric strategies towards a more holistic…

Connecting Data to Improve Your Contamination Control Strategies

Contamination control is absolutely critical in the pharmaceutical industry and includes particulate, microbial, product carryover, chemical, and viral aspects of contamination and often involves proactive, reactive, and supporting aspects. However, regulations, liabilities, and patient health added to the mix create data silos that often form multiple processes and make it difficult to create efficient and…

Revolutionizing the Audit Process: Advancements in Supplier Assessments Within the Pharmaceutical Sector

Pharmaceutical companies invest significant resources in research and development to discover new drugs and therapies and improve existing ones. This involves rigorous testing, clinical trials, and obtaining regulatory approval before a drug can be sold. Government agencies, such as the Food and Drug Administration (FDA) in the United States, oversee the approval process and conduct…

How Life Science Manufacturing Facilities Can Successfully Adapt To Change

In this podcast episode of “Exceeding Your Benchmark,” host Gabrielle is joined by Ashley Harp, Lead Process Engineer at CRB. They discuss the challenges manufacturing facilities like Life Science Companies are facing as they adapt to new technologies and advancements in manufacturing, specifically in the area of combining highly potent active pharmaceutical ingredients (HPAPIs) and…

How Cell and Gene Manufacturers Can Scale to Meet Demand

Between 2022 and 2030, the cell and gene therapy sector is expected to experience a compound annual growth rate (CAGR) of 39.42 percent, BioSpace said of a recent Vision Research Report. This is quite a large anticipated growth; how will startups and current manufacturing companies work to meet this growing demand? On today’s episode of…

What Updated Annex 1 Regulations Mean for Sterile Manufacturing Companies in 2023

Over the summer new GMP Annex 1 regulations were released by the FDA and EMA, prompting new changes to become standard protocolin sterile manufacturing companies. By August 2023, the regulations will take effect and companies will have to ensure that they are in compliance with the guidelines set. Discussing this on a new podcast, host…

Expert Insights

Mastering Manufacturing Equipment Validation and Qualification Hinges on Developing a Strategic Plan and Then Executing it Flawlessly

Validation and qualification are some of the most critical phases in the lifecycle of equipment and processes within industries like pharmaceuticals and manufacturing. Driven by the necessity to adhere to stringent regulatory standards and ensure high operational efficiency, the distinction between ‘qualification of equipment’ and ‘validation of processes’ becomes paramount. As the landscape of…

Benchmark Products Bioprocessing Solutions Provide Single-Use Solutions for Customers

Benchmark provides a new bioprocessing solution to maximize efficiency. This is a single-use system for pharma manufacturers for filling, mixing and single-use assemblies.

Early Defined Processes and a Documented Plan Are Crucial in the Commissioning of GMP Facilities

Commissioning Good Manufacturing Practice (GMP) facilities is a critical yet complex component of the manufacturing sector, especially as facilities grow in sophistication and the standards for quality and safety heighten. Ensuring that clean rooms, HVAC controls, power systems, and other utilities meet stringent requirements is no small feat. Challenges such as permit delays, documentation…

Setting the Benchmark: Adapting to Evolving Life Science Regulations with Benchmark Products

How can life science companies navigate the challenges posed by rapid technological changes and the latest life science regulations, such as the recent EU GMP Annex I regulations for the manufacture of sterile medicinal products? Tom Caffery, CEO of Benchmark Products, highlighted the importance of adapting quality assurance practices and investing in updated facilities…

Beyond Compliance: Benchmark Products Delivers Next-Level Cleanroom Solutions

The stakes for maintaining pristine cleanroom facilities are higher than ever in the pharmaceuticals and manufacturing sectors. Innovations and quality standards in this niche are not just about staying competitive; they’re about setting new benchmarks for excellence and reliability. This is where companies like Benchmark Products come into play, distinguishing themselves through a relentless…

Benchmark Products: Revolutionizing Cleanroom Management with Tailored Efficiency and Compliance Solutions

Pharmaceuticals and manufacturing cleanrooms play a pivotal role in ensuring product safety and compliance with industry standards. These controlled environments are critical for the prevention of contamination and for maintaining the integrity of the manufacturing process. However, managing a cleanroom is fraught with challenges, including maintaining stringent cleanliness standards and adapting to the unique…

Transforming the Pharma Supply Chain: Reduce Your Ecological Footprint by Embracing Green Packaging and Energy Efficiency

In the pharmaceutical industry, where the supply chain’s complexity often complicates sustainability efforts, Benchmark Products is emerging as a beacon of environmental responsibility. Through a strategic blend of green packaging, energy-efficient operations, and waste reduction, Benchmark Products not only addresses its ecological footprint but also sets a precedent for the sector. This comprehensive approach…

Benchmark Product’s Customer-Centric Solutions: Achieving Reliability with a Robust Supply Chain

In an era where supply chain disruptions have become all too common, businesses are striving for solutions that ensure reliability and continuity for their customers. The key to navigating this challenging landscape lies in proactive planning and the implementation of robust supply chain strategies. These strategies not only aim to mitigate disruptions but also…

Digital Therapeutics: The Future of Chronic Disease Management is Here!

The intersection of technology and healthcare has ushered in an era of unprecedented innovation, transforming the way chronic and complex conditions are managed and treated. From digital therapeutics offering bespoke management plans for chronic diseases to the groundbreaking potential of RNA-based treatments in gene regulation, the horizon of medical possibilities is expanding. This fusion…

Bigger Profits, Better Decisions: The Transformative Impact of Integrating AI and IoT into Supply Chains

How are AI, IoT, and data analytics transforming the challenges of supply chain management into opportunities for unprecedented efficiency and resilience? On an episode of Expert Insights by Benchmark Products, Daniel Litwin, the Voice of B2B at MarketScale, emphasizes the transformative impact of integrating AI and IoT into supply chains. This integration facilitates data-driven…

Year in Review: Benchmark Products Leads in Cleanroom Technologies and Personal Protective Equipment

The past year has been a landmark period for the pharmaceutical industry, with Benchmark Products at the helm of thought leadership in cleanroom technologies and personal protective equipment (PPE). As we navigate through the complexities of pharmaceutical manufacturing, the insights from Benchmark Products have provided a guiding light for innovations in safety and efficiency….

Pharma & Life Sciences Gain an Efficiency Upgrade Through Robotics

How is the integration of robotics transforming the pharmaceutical and life sciences industries into more efficient, safe, and innovative fields? Gabrielle Bejarano, representing Benchmark Products, sheds light on the significant impact of robotics and automation technologies, emphasizing their role in enhancing operational efficiency and safety across drug development and manufacturing processes. “The COVID-19 pandemic…

Enhancing the Life Science Supply Chain Through Lean and Just-in-Time Manufacturing

How can lean and just-in-time manufacturing significantly enhance the efficiency and responsiveness of supply chains, particularly in the critical field of life sciences? Wesley Boyce, Professor of Supply Chain Management & Logistics at The University of Nebraska-Lincoln, offers valuable insights into this question, particularly highlighting how these methodologies can drastically reduce lead times, improve…

HVAC Trends in Maintenance and Regulations

As the HVAC industry navigates through evolving EPA regulations, Greg Crumpton, VP of Critical Environments and Facilities at Service Logic and host of the Straight Outta Crumpton podcast, sheds light on the significant changes affecting clean room designs and system maintenance. In this episode of Benchmark Products’ Expert Insights series, Crumpton discusses the shift…

Sightline Respirator Product for Maximum Visibility in Sterile Pharmaceutical Manufacturing

On the latest episode of Expert Insights, presented by Benchmark Products, host Jennifer Parker sat down with Greg Steller, National Account Manager for Bullard™, to discuss Bullard’s groundbreaking Sightline product. The Sightline respirator, designed for sterile pharmaceutical manufacturing, offers a 320-degree panoramic viewing lens to ensure maximum visibility and reduce operator claustrophobia. Stellar emphasized…

HVAC Requirements for Cleanrooms

In this episode of Expert Insights, presented by Benchmark Products, Greg Crumpton, VP at Service Logic and host of the Straight Outta Crumpton podcast, discusses the specialized HVAC requirements for cleanrooms. He explains that, unlike ordinary settings, cleanrooms demand advanced filtration to maintain a controlled environment, preventing contamination and ensuring the integrity of the…

Filtered Air for Pharma Workers: Powered Air Purifying Respirators Take Center Stage

Powered air purifying respirators (PAPRs) are vital in the pharmaceutical industry to ensure worker safety. Greg Stellar, a National Account Manager at Bullard, provides valuable insights into the different types of respirators available, including powered air purifying respirators (PAPRs), for solid dose and cleanroom environments in pharma. Powered air purifying respirators is a cutting-edge…

Aseptic Processing: Creating Optimal Conditions for Clean Room Design

Aseptic processing is a critical aspect of the pharmaceutical and life science industry, where maintaining sterile and controlled environments is of utmost importance. In our discussion today, we are joined by Matt Ferrin, CFO and COO of Benchmark Products, and Mike Kosinski, President of CEPro, Inc, as they delve into the key aspects of…

Frequency of HVAC Maintenance

In this episode of Expert Insights, presented by Benchmark Products, Greg Crumpton, VP at Service Logic and host of the Straight Outta Crumpton podcast, advises on the frequency of HVAC maintenance. Crumpton suggests following the OEM’s guidance and being especially aware of a company’s operating conditions, geographic location, and ambient weather, as these can…

Particle Shedding in Clean Rooms: Laundered vs. Single Use – The Surprising Verdict

Particle Shedding in Clean Rooms: In an increasingly cleanliness-obsessed world, it’s becoming evident that choices regarding the materials we use have far-reaching impacts. This is particularly true in highly controlled environments like clean rooms, where the importance of minimizing particle shedding is paramount. The question arises as to whether reusable or single-use garments should…

Unleashing the Power of Flexible Isolators: Insights from Onfab’s Director Mike Brown

Flexible isolators are a crucial component in pharmaceutical processing, and Onfab’s Director and Containment Specialist, Mike Brown, offers invaluable insights into their applications. Boasting an impressive repertoire of over 6,500 designs, Onfab caters to diverse processing parameters and GMP classifications, providing comprehensive solutions to meet various requirements. The retrofit isolators offered by Onfab elevate a…

Benchmark Products Corporation

Benchmark Products Introduces Benchmark Bioprocessing Solutions: Single-Use Assemblies Tailored for Life Science Manufacturers

Benchmark Products has introduced its new Benchmark Bioprocessing Solutions, a comprehensive offering of customizable single-use assemblies tailored for life science manufacturers. Guided by a customer-centric philosophy, the team at Benchmark understands that every biopharmaceutical process presents unique challenges. By conducting detailed analyses of client workflows, Benchmark identifies opportunities to enhance efficiency, reduce costs, and…

Innovation and Excellence in Life Sciences: Benchmark Products’ Year in Review

In 2024, Benchmark Products redefined progress with pioneering innovations in life sciences and pharmaceutical manufacturing. At Interphex in New York City, the company showcased its range of life science and pharmaceutical manufacturing products, including the innovative BioMark Bags. These single-use bioprocessing solutions are recognized for their robust durability, chemical resistance, and compliance with FDA…

Driving Cleanroom Innovation for a Sustainable Future with Benchmark Products

At Benchmark Products, sustainability is at the heart of everything we do. We are committed to providing smart solutions for cleanroom disposable products, ensuring that recycling is performed effectively and responsibly. Our Benchmark GMP and Suite products are designed not only for top performance but also with the environment in mind. Our innovative solutions…

Tour Benchmark Products: Pioneering Cleanroom Solutions for Life Sciences

Get a feel for Benchmark Products cleanroom solutions for life sciences manufacturing customers with this mini tour of their facility.

Benchmark at Interphex 2024

Benchmark Products showcased their line of life science and pharmaceutical manufacturing products during Interphex in New York City April 2024.

Benchmark Products: Pioneering Excellence in Cleanroom Solutions for Pharmaceuticals and Life Sciences

In the demanding world of pharmaceuticals and life sciences, precision, and compliance are not just objectives; they are imperatives. Benchmark Products stands at the forefront of this industry, offering a comprehensive suite of cleanroom products and services tailored to meet the specialized needs of these sectors. With a promise of high-quality solutions and a…

Cleanrooms in 60 Seconds - Mary Kate Campbell

My Biggest Takeaway from NC State’s Bioprocessing Course

Hands-on immersion has become a defining advantage in modern biomanufacturing, and programs like NC State’s BTEC exemplify why experiential learning matters as much as technical knowledge. By stepping through a full upstream and downstream bioprocess in a simulated environment, the Benchmark team gained firsthand insight into the real-world pressures, decisions, and constraints their customers…

Why Single – Lot Shipments Matter to QA

In modern warehouses, what looks like a minor issue at receiving can quickly escalate when a lot lacks the right certifications or falls out of spec, triggering quarantine, added paperwork, and intense traceability demands on quality teams. As supply chains grow more complex and regulated, these friction points quietly drain time and increase the…

3 Simple Changes to Improve Your CCS

Contamination control failures rarely stem from complex science; more often, they’re the result of everyday practices that haven’t evolved with modern cleanroom demands. Simple shifts—like cleaning in a strict top-to-bottom flow, choosing materials that trap submicron particles instead of redistributing them, and standardizing tools so operators aren’t improvising—can dramatically reduce risk while improving efficiency….

How to Avoid Stockouts in Cleanroom Consumables

In an era where supply chain volatility can stall production overnight, smart inventory strategy has become a competitive advantage. Benchmark’s no-cost inventory reserve model flips the traditional risk equation by letting manufacturers lock in dedicated stock—on their own timeline—without tying up capital or warehouse space. It’s a practical reminder that reliability isn’t just about…

How to Clean Large Corridors Faster

In many industrial and CNC environments, cleaning routines quietly drain productivity because teams rely on tools designed for much smaller spaces. Upsizing something as simple as a mop—from a 16-inch head to a 36-inch, purpose-built option—can dramatically reduce fatigue while helping crews cover more ground in less time. It’s a reminder that operational efficiency…

The Cleaning Mistake Slowing Down Room Changeovers

Cleanroom changeovers often drag on not because of operator error, but because outdated or inefficient cleaning materials force teams into repetitive work that quietly erodes productivity. As manufacturers tighten contamination controls and uptime expectations, investing in higher-efficiency cleaning tools—and updating SOPs to match—has become a practical way to reclaim hundreds of lost hours each…

Annex 1 Cleaning

Annex 1 didn’t merely refine regulatory language—it fundamentally reshaped expectations around how cleanrooms are cleaned, emphasizing contamination control strategies, residue-free performance, and repeatable processes that work right the first time. As manufacturers adjust, tools and materials like advanced ultrafiber technologies are becoming essential because they support consistent first-pass cleaning without shedding or compromising sterility….

A Simple Fix For Tubing Chaos

In regulated cleanroom environments, small oversights like tubing dragging on the floor or taped makeshift supports can quietly undermine both contamination control and operator safety. As facilities push for higher throughput and stricter compliance, purpose-built solutions such as elevated tubing management systems are becoming less of a convenience and more of an operational standard. By…

Cleanrooms in 60 Seconds - Kirk Whitmer

What’s One Detail Teams Often Miss in Contamination Control

In contamination-controlled environments, teams often focus on cleaning frequency and protocols while overlooking a more foundational question: what microorganisms are actually present. Without proper microbial identification, facilities risk choosing disinfectants that are poorly matched to their real contamination threats, undermining even the most rigorous cleaning programs. For manufacturers like Benchmark Products, this gap highlights…

Has Your Home Cleaning Game Leveled Up Since Joining Benchmark

Joining a company that lives and breathes cleanliness can subtly transform daily routines, especially at home. For families with young children, having access to high-quality cleaning products isn’t just about sparkling surfaces—it becomes part of a broader strategy to navigate cold and flu season with a bit more confidence. In that sense, Benchmark Products…

How Critical is it To Keep Up With Client Needs and Industry Shifts

In highly regulated industries, keeping pace with client needs and industry shifts isn’t optional—it’s foundational to trust. For Benchmark Products, staying ahead of evolving regulatory guidance means translating complexity into clarity, helping customers remain compliant without slowing their operations. By shouldering that burden and proactively adapting products or processes, Benchmark positions itself not just…

Why Does Benchmark’s Work Need More Visibility

In an industry defined by rapid scientific breakthroughs, Benchmark Products plays a quietly pivotal role—translating innovation into tangible tools that life sciences manufacturers can actually use. By staying aligned with the evolving needs of patients and producers alike, Benchmark has built a reputation for agility, rapidly manufacturing solutions that improve efficiency and enable new…

Why Does Benchmark’s Work Matter, and What’s it Like Being Part of it

Working behind the scenes of pharmaceutical manufacturing may not always be visible to patients, but it is foundational to every breakthrough therapy that reaches them. At Benchmark Products, the work matters because it supports the precision, efficiency, and reliability life sciences companies need to turn complex science into scalable, life-saving treatments. Being part of…

What Data-Driven Assumptions Do Clients Need to Rethink

Too often, organizations treat consumables as a simple unit-cost line item, overlooking how material selection directly affects efficiency, equipment longevity, and environmental monitoring outcomes. When clients rethink this assumption through a data-driven lens—especially in cleaning and disinfection—they uncover returns in reduced waste, improved EM performance, and the ability to run more effective campaigns throughout the…

Wiping or Mopping: What Would You Demo and Why

For decades, cleanroom wiping practices have borrowed heavily from the semiconductor industry, but the quarter-fold method and its standard polyester substrate are increasingly showing their age. Today’s environments demand more durable, higher-performance materials that last longer, reduce waste, and deliver more consistent results. For Benchmark Products, the real demo isn’t just wiping or mopping—it’s…

What’s the One Mistake You Correct Most Often in Cleaning or Disinfecting

In cleaning and disinfecting, the most common mistake isn’t doing too little—it’s doing too much with the wrong product. Facilities often default to highly aggressive disinfectants like sporicides in a “spray and pray” mindset, overlooking how overuse can quietly degrade equipment, damage surfaces, and even shorten a facility’s operational lifespan. Smart disinfection is about…

How Can Switching to a Better-Performing Wipe Impact Efficiency and Contamination Control

Switching to a higher-performing wipe can be a deceptively simple upgrade with outsized operational impact, especially in controlled environments where efficiency and contamination control are non-negotiable. When a single wipe lasts eight to twelve times longer, teams reduce waste, minimize changeovers, and improve environmental monitoring consistency—cutting down on costly investigations over the course of the…

How Can Manufacturers Maximize ROI on Cleanroom Consumables

Maximizing ROI on cleanroom consumables requires manufacturers to look beyond unit price and evaluate total operational impact—from supply chain reliability to how products influence cleaning time and environmental monitoring outcomes. Inferior materials may appear cost-effective upfront, but they often demand more disinfectant, more labor, and more downtime, quietly eroding productivity. For manufacturers partnering with…

Why Should Companies Invest in Higher Quality Solutions

In an era where cost-cutting often trumps common sense, many organizations overlook how false economies quietly erode operational efficiency. Cheaper, lower-quality products may look good on a spreadsheet, but their excessive use drives waste, sustainability setbacks, and inconsistent outcomes. Investing in higher-quality solutions flips that equation—delivering better performance with less material, stronger results, and…

What’s the biggest mistake you see people make when tackling a task

Across industries, the most common productivity bottleneck isn’t a lack of talent, but the quiet persistence of outdated tools and routines. As workflows become more complex and technology advances, choosing the right tool for the job can mean the difference between wasted time and meaningful progress. The challenge—and opportunity—lies in questioning old habits and recognizing…

Cleanrooms in 60 Seconds - Will Sepsis

Why Is the Mission of Benchmark So Important

As pharmaceutical innovation accelerates, the margin for error narrows, making quality assurance not just a regulatory necessity but a public good. Benchmark’s mission sits at the intersection of progress and protection—helping manufacturers stay aligned with FDA standards so life-saving therapies reach patients faster and safer. By keeping cleanrooms compliant and companies out of trouble, Benchmark…

What Is It Like for You to Be Part of the Benchmark Products Teams Now

Being part of the Benchmark Products team today means working at the intersection of precision manufacturing and deeply human collaboration, especially in the high-stakes world of cleanroom and sterility assurance solutions. As the organization grows, employees describe a culture that still feels familial—one where clear communication, personal accountability, and genuine care for customers drive…

Do Your Friends Ever Ask You For Cleaning Tips

In a media landscape increasingly shaped by privacy constraints, data clean rooms have emerged as a quiet but powerful way for brands to collaborate without exposing sensitive information, even if, as Will Sepsis quips, some partners would still prefer that “ignorance is bliss.” That tension—between curiosity and caution—captures the moment we’re in, where understanding…

Do You Friends Ask You For Cleaning Methods or Clean Their Home

At Benchmark Products, where cleanroom precision is part of everyday work, professionals often discover that specialized knowledge doesn’t always translate neatly into casual conversations—especially when friends jokingly wonder if you’ll critique their homes or turn them into germaphobes. The reality is that cleanroom science is about controlled environments and risk mitigation at an industrial scale,…

Has Working at Benchmark Made You Cleaner at Home

At Benchmark Products, where clean room discipline is second nature, the habits forged on the job often follow employees home, turning everyday chores into a mindful extension of professional rigor. As voices like Will Sepsis illustrate, working in environments where precision cleaning protects products and people alike can quietly reshape how you see a…

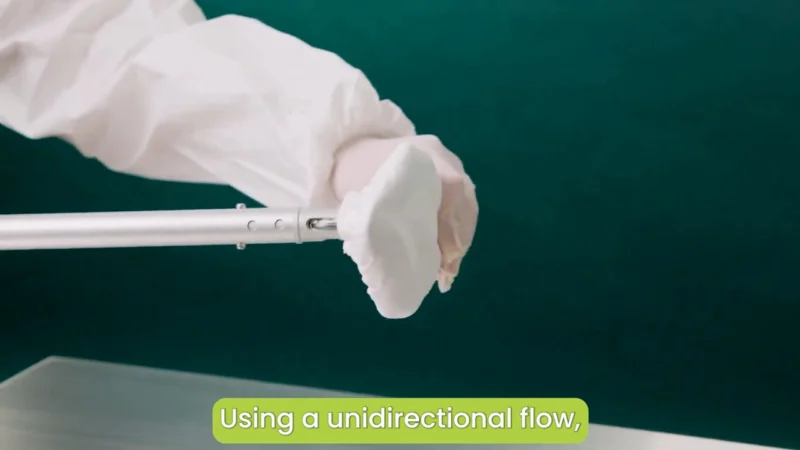

How Does Benchmark’s Reach Tool Help Cleanroom Teams Improve Compliance

In highly regulated cleanroom environments, compliance often hinges on what teams can’t easily see or reach. Benchmark’s Reach Tool extends ultrafiber cleaning technology into isolators, pass-throughs, and other constrained spaces while preserving unidirectional airflow—helping cell therapy teams, tissue banks, and CDMOs maintain consistent contamination control without compromising process integrity. By pairing smart design with…

What’s One SOP or Protocol You Wish Every Cleanroom Leader Would Rethink

Too many cleanroom teams still assume that more disinfectant is the answer, but Annex 1 makes it clear that residues left behind can quietly undermine even the most aggressive cleaning regimes. Without a deliberate residue breakdown step—such as a validated rinse—bioburden can persist beneath the surface, driving CFU formation and downstream environmental monitoring failures….

Why is What Benchmark Product Does So Important For You and Your Family

At Benchmark Products, the work done behind the scenes in clean rooms quietly safeguards lives, ensuring that the drugs and therapies families rely on are manufactured under the highest standards of safety and sterility. When those products are used by real people—parents, children, or even a close relative on dialysis—the mission becomes deeply personal,…

What Makes the Suite Ultra-Fiber Wipe Different From the Rest

In controlled environments where contamination is measured in microns and margins for error are razor thin, the Suite Ultra-Fiber Wipe from Benchmark Products stands apart by rethinking what microfiber can do. By engineering fibers that are dramatically smaller than standard polyester microfiber, the wipe delivers measurable gains in residue removal, bio-burden reduction, and endotoxin…

What Exactly Is a 5-Log Reduction, and Why Does It Matter for Cleanroom Teams

In cleanroom environments, contamination control isn’t about vague cleanliness—it’s about measurable reductions, and a 5-log reduction means cutting microbial presence by 99.999%, turning 100,000 bacteria into just one. For cleanroom teams, this level of performance before disinfectants are even applied is critical, because it dramatically lowers bioburden risk and strengthens the effectiveness of every…

What led you to Benchmark Products

For many professionals, the path into life sciences isn’t sparked by spreadsheets or strategy decks, but by a deeply human moment that reveals how invisible systems quietly sustain life. Will Sepsis’s journey to Benchmark Products grew from witnessing a family member rely on in-home dialysis, an experience that exposed how sterility assurance—often overlooked outside…