Kuka Robotics (AG)

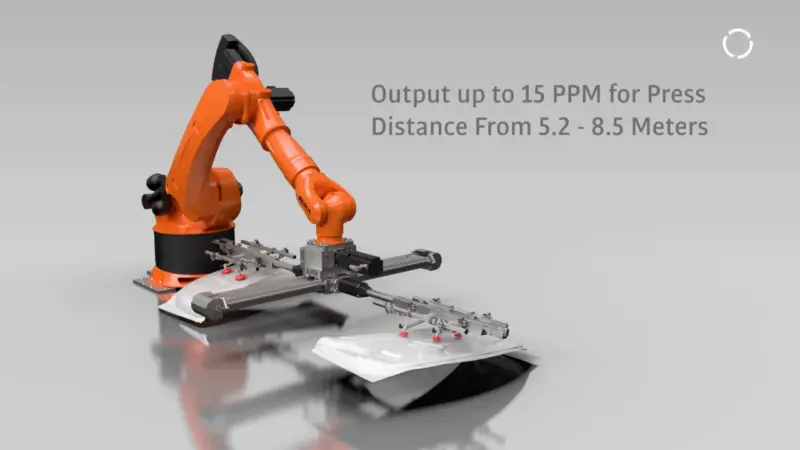

One of the major hurdles manufacturers face today is integrating, optimizing, and maintaining press automation systems. From ensuring high cycle speed stability to managing the complex task of part transfer, manufacturers are constantly on the lookout for ways to streamline operations and enhance productivity. This urgent need for better press automation tools is met by…

Latest

Community Generated Content - Kuka Robotics (AG)

Optimizing Welding Quality with KUKA.EqualizingTech: The Future of Industrial Manufacturing

For manufacturers, achieving consistently high welding quality is a complex problem. Any slight misalignment or miscalculation in force can lead to bending of sheet metal, inaccurate welding force, and ultimately, defective welds. Traditional welding guns use mechanical equalizing systems to combat these issues, but this solution isn’t without its drawbacks. These systems are often complicated,…

Community Generated Content - Kuka Robotics (AG)

Transforming Aluminum Resistance Welding: Introducing KUKA.RoboSpin

In manufacturing, the complexity and challenges of welding aluminum components have long been a roadblock. Aluminum’s inherent properties, including surface oxidation and the propensity to build up caps, interfere with welding quality and efficiency. This not only increases time and cost but also shortens the lifespan of welding tips. KUKA, an industrial automation pioneer, has…

Community Generated Content - Kuka Robotics (AG)

Unleashing the Future of Automotive Manufacturing with KUKA.ServoGunAdvanced

In today’s advanced automotive manufacturing landscape, the emphasis on the use of lightweight materials such as high-strength steel grades, aluminum, and aluminum alloys has never been greater. As industries evolve, they necessitate the development of innovative technologies to ensure the highest quality spot welds, given these materials require a high degree of force accuracy. For…

Community Generated Content - Kuka Robotics (AG)

Revolutionizing Welding Calibration: The Efficient, Precise, and Flexible KUKA.ServoGun

The world of manufacturing is continuously challenged by the demand for precision, efficiency, and reliability. Especially in welding operations, the quality of results heavily depends on achieving accurate and consistent pressures, which can be a labor-intensive and time-consuming process. This is where the KUKA.ServoGun steps in, fundamentally transforming the traditional welding calibration process to drive…

Community Generated Content - Kuka Robotics (AG)

Mastering Precision in Spot Welding Operations: KUKA.ServoGunBasic Streamlines Manufacturing

Industrial manufacturers face a myriad of challenges, with one of the most critical being achieving consistent, high-quality spot welding. Factors such as gun positioning, weld force, and dynamic gun compensation directly impact the quality and integrity of the welds. Manufacturers have long depended on standard torque-controlled guns, which use motor current to reach the target…

Community Generated Content - Kuka Robotics (AG)

Revolutionizing Manufacturing: The Power of KUKA’s ServoGun Family For Spot Welding

In the high-speed and precision-demanding world of manufacturing, any slight error in spot welding can result in costly and time-consuming reworks, and even product recalls. Manufacturers are constantly challenged with maintaining consistent welding quality, dealing with hard-to-weld materials, minimizing maintenance costs, and preventing rapid welding tip wear. The ultimate solution to these problems lies not…

Latest

Latest Community Generated Content - Kuka Robotics (AG)

Optimizing Welding Quality with KUKA.EqualizingTech: The Future of Industrial Manufacturing

For manufacturers, achieving consistently high welding quality is a complex problem. Any slight misalignment or miscalculation in force can lead to bending of sheet metal, inaccurate welding force, and ultimately, defective welds. Traditional welding guns use mechanical equalizing systems to combat these issues, but this solution isn’t without its drawbacks. These systems are often complicated,…

Transforming Aluminum Resistance Welding: Introducing KUKA.RoboSpin

In manufacturing, the complexity and challenges of welding aluminum components have long been a roadblock. Aluminum’s inherent properties, including surface oxidation and the propensity to build up caps, interfere with welding quality and efficiency. This not only increases time and cost but also shortens the lifespan of welding tips. KUKA, an industrial automation pioneer, has…

Unleashing the Future of Automotive Manufacturing with KUKA.ServoGunAdvanced

In today’s advanced automotive manufacturing landscape, the emphasis on the use of lightweight materials such as high-strength steel grades, aluminum, and aluminum alloys has never been greater. As industries evolve, they necessitate the development of innovative technologies to ensure the highest quality spot welds, given these materials require a high degree of force accuracy. For…

Mastering Precision in Spot Welding Operations: KUKA.ServoGunBasic Streamlines Manufacturing

Industrial manufacturers face a myriad of challenges, with one of the most critical being achieving consistent, high-quality spot welding. Factors such as gun positioning, weld force, and dynamic gun compensation directly impact the quality and integrity of the welds. Manufacturers have long depended on standard torque-controlled guns, which use motor current to reach the target…

Revolutionizing Manufacturing: The Power of KUKA’s ServoGun Family For Spot Welding

In the high-speed and precision-demanding world of manufacturing, any slight error in spot welding can result in costly and time-consuming reworks, and even product recalls. Manufacturers are constantly challenged with maintaining consistent welding quality, dealing with hard-to-weld materials, minimizing maintenance costs, and preventing rapid welding tip wear. The ultimate solution to these problems lies not…